I bought the lathe track system from WoodTurning Wonders. I modified it a bit to make it easier to use on my Jet 1221VS midi lathe. You can see my video here

View: https://www.youtube.com/watch?v=ybBmI1I7Vyc

-

Beware of Counterfeit Woodturning Tools (click here for details) -

Johnathan Silwones is starting a new AAW chapter, Southern Alleghenies Woodturners, in Johnstown, PA. (click here for details) -

Congratulations to Keven Jesequel for "Big Leaf Maple" being selected as Turning of the Week for April 15, 2024 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The most useful dust hood holder is.....

- Thread starter John Hicks

- Start date

I bought the lathe track system from WoodTurning Wonders. I modified it a bit to make it easier to use on my Jet 1221VS midi lathe. You can see my video here

View: https://www.youtube.com/watch?v=ybBmI1I7Vyc

Ronald nice video. You can remove he adapter from your hose and screw the hose directly to the hood, can't you?

Thanks, Gerald. Although you can screw the hose directly to the hood, it would be very cumbersome in my set-up. In my set-up, I move the 4" hose among machines (band saw, drum sander, planer, router table, etc.). In addition, I disconnect the 4" hose and use it directly for clean-up around the lathe as well as when I roll the lathe against the garage wall when done using it. Thus, it is important that I can quickly connect/disconnect the 4" hose. Also, if you directly screw-in the hose into the hood, the hose will naturally tend to unscrew into its untwisted shape. Thus, you have to pre-twist the hose several turns so that it will twist on properly without tending to unscrew itself.Ronald nice video. You can remove he adapter from your hose and screw the hose directly to the hood, can't you?

If you have a set-up where the 4" hose is dedicated to the lathe, then you are correct that directly attaching it to the hood would work fine without the need for an adapter.

Thanks, Gerald. Although you can screw the hose directly to the hood, it would be very cumbersome in my set-up. In my set-up, I move the 4" hose among machines (band saw, drum sander, planer, router table, etc.). In addition, I disconnect the 4" hose and use it directly for clean-up around the lathe as well as when I roll the lathe against the garage wall when done using it. Thus, it is important that I can quickly connect/disconnect the 4" hose. Also, if you directly screw-in the hose into the hood, the hose will naturally tend to unscrew into its untwisted shape. Thus, you have to pre-twist the hose several turns so that it will twist on properly without tending to unscrew itself.

If you have a set-up where the 4" hose is dedicated to the lathe, then you are correct that directly attaching it to the hood would work fine without the need for an adapter.

Ok try another route. Cut a piece of 4" and get a adapter that will fit into your existing adapter . Screw the hose on the setup and the new adapter into the hose and then you will have the quick connect you need

I just got Ken Rizza's track system to hold my dust hood. I like it better than anything I've bought or jury rigged so far. https://woodturnerswonders.com/collections/lathe-track

This system looks very versatile and effective. Anyone else have experience with it?

Clark, I've had this setup for a few weeks. I thought I would out smart the track system and mount the arms to the wall. I found out real quick it's a hassle with a larger dia. turning, so its back to the stock setup.This time I mounted the track off center towards the tailstock as to not interfere with the PM banjo when turning small dia. I really like the PowerMatic Lathe but there is nuthin powermatic about moving that banjo around all day!!

Attachments

Thanks for the feedback.Clark, I've had this setup for a few weeks. I thought I would out smart the track system and mount the arms to the wall. I found out real quick it's a hassle with a larger dia. turning, so its back to the stock setup.This time I mounted the track off center towards the tailstock as to not interfere with the PM banjo when turning small dia. I really like the PowerMatic Lathe but there is nuthin powermatic about moving that banjo around all day!!

Glenn, those look nice. My first concern would be are they sturdy enough for shop use??? I tend to break things. "Honest mom, all I did was touch it!"

robo hippy

robo hippy

Are you still using this collection system?Well, here is an older video I did about my dust collection system:

View: https://www.youtube.com/watch?v=AZsVc7qVx7A

I am in the process of 'new and improving' it. The problem with this one was that I didn't make it some thing that stayed in place, and had to set it up and take it down for sanding. So, the basic concept worked excellently. I went to the local plastic supply place and found out I could order 5 by 10 foot sheets of the plastic that the barrel is made from, so I ordered 2 sheets that were 1/4 inch thick. Next time, I will order 3/16 inch if it is available, or maybe even 1/8 inch. They are currently wrapped up, and I go back and cinch them up more tightly every day or three to get them to assume a more round shape. They will be screwed to the wall and a wood frame around the lathe, and I will have partitions for bowl sanding to more confine the dust plumes/clouds. They will be tall enough that I can stand under them without bumping my head, about 6' 3", and and I may even put a LED light under it for general lighting. The one in the video may go to the mini lathe, again, some thing I can leave in place while I turn. Oh, I will get some swimming pool noodles to cover the top edge. Shape will be a more open C shape, and possible drop down or slide on poly carbonate shield for when I am sanding bowls. I will do another video about the new versions, and have to build 3 total for my bigger lathes.

The entire concept is that the more enclosed your piece is, the more dust you collect at the source, and the less there is that goes into the air. I have seen cardboard boxes, lamp shades, and even plywood boxes. A club could probably do a group purchase on a few sheets of the plastic. I am considering a formed poly carbonate one for my American Beauty, which will probably be the primary demonstration lathe in my shop. they can bend that stuff, and you can see through it for demonstration purposes.

robo hippy

Yes. Still trying to 'new and improve' it. I like the idea some one here had about hinged wings and a lid. I like the idea of a track system of some sort. I do want one that can stay in place while I turn as well as when I sand.

robo hippy

robo hippy

HC Black Hole Dust Catcher System

Sanding dust not only makes a mess of the shop, it’s also a long term health risk that should be taken seriously. The Black Hole Dust Collector is a well designed collection system with everything you need to get up and running fast, while being simple to install. The fully adjustable dust hood...

This is the link for the Black Hole. It is a little pricey but it's ready to install and use and I don't believe there is really any lathe that it doesn't work with. Comes with the aluminum track, hood, clamps, mounting post for the hood and a short section of flexible hose (not great hose though), all ready to mount on the lathe and connect to a dust collector. For me, it works great and I didn't want to spend a lot of time making something. Connected to my cyclone it collects a very high percentage of the fine dust from turning and sanding and even some of the smaller shavings. I love it. It might not be a good solution for everyone.

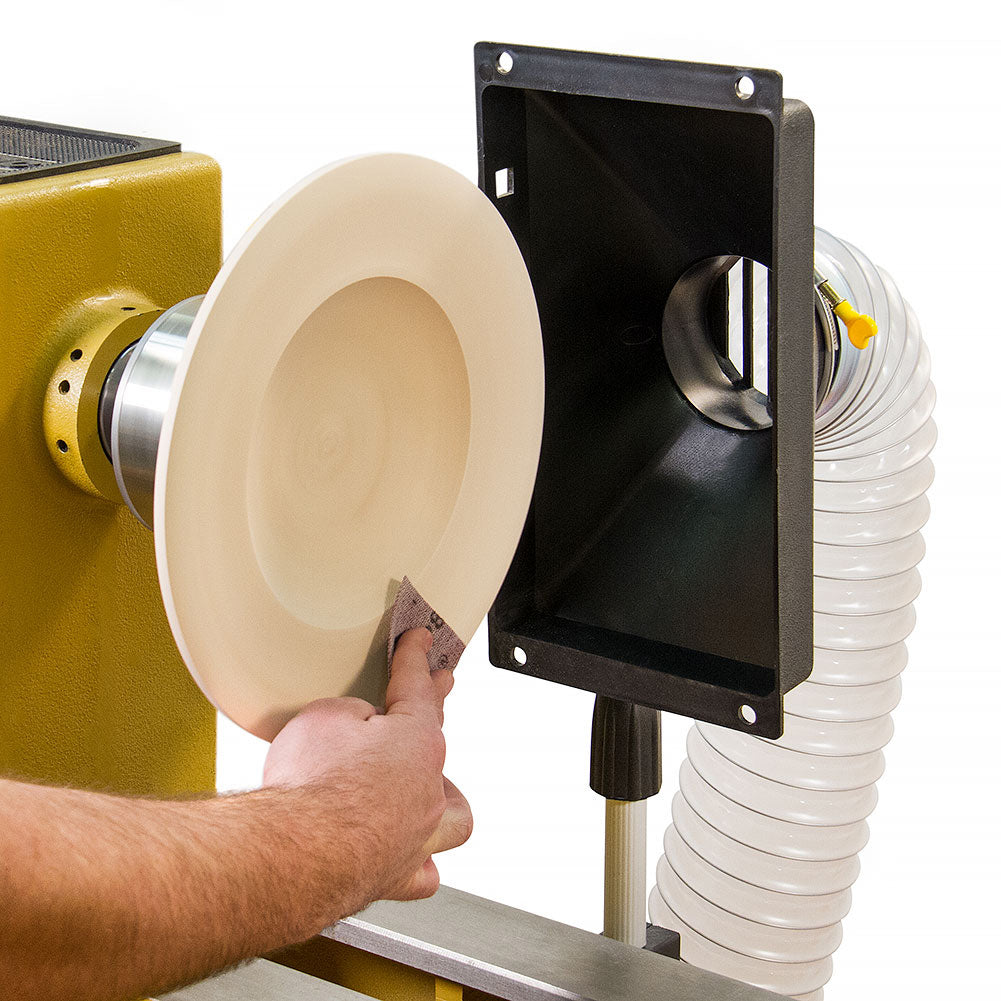

I use the one from wood turners wonders. It comes with a bracket that clamps to the back of the lathe; and two bendable arms that hold the 4' hose. I also use the light mount. I found it to be very useful; although it gets in the way when sliding the headstock to the other end for hollowing. This pic is from his site.

I haven't been able to break it yet. I would say the bracket it mounts too needs to be a bit longer though.

I haven't been able to break it yet. I would say the bracket it mounts too needs to be a bit longer though.

+1 for the system from Woodturners Wonders ... I have one installed on each lathe. I like the flexible goosenecks ... easy to reposition. Previously had a knock-off similar to the Black Hole ... always had problems repositioning it due to the stiff aluminum arm.

Glad to hear the positive reviews of the wood turners wonders system. I'm sure Santa has one for me.