Instead of resurrecting an old thread link here I wanted to start fresh. Don't know who's still around.

I'm looking for current best practices to make the Crushgind mechanism's 2 main bores. I have the notch tool for the "clips", I do not plan to use glue.

From that old thread:

I have a new crushgrind mechanism and their current instructions. I'm trying to optimize the forstner bits I need to do this as I plan to get some higher end Bormax 2/3 forstners.

For the CrushGrind® Shaft instructions, they call for 22mm and 38mm bores to fit the Crushgrind's upper and lower bodies, as John Mentioned in the past. I have a mechanism in hand that I'm measuring. The measurements in the instructions are pretty much the diameter of the respective bodies not including the anti-rotation ribs meant to penetrate wood.

Researching the woodturning community, I see some people/videos using SAE bits that are a 1/16" larger than those recommended bores (15/16 vs. 7/8 and 1-9/16 vs 1-1/2"), and John who posted with certainty to use the size bores in the instructions (7/8" and 1-1/2"). I saw where Brian Horais (RIP) cut the anti rotation ribs off and used 1.5" bores. I'll be using hard woods and I'm concerned those anti-rotation ribs are not going to make that much of an indentation. So, I can press one of these into the 38mm/1-1/2 bore for example, but I'm worried about damaging the mechanism as those ribs aren't going to cut their depth, I don't think.

Anyone have current guidelines and experience with the bores that are best to use? Without using glue.

I've considered using the Woodcut tools Mill to do these. I've encountered more than one person who said they had it but didn't use it preferring the finish of forstners. I like that it is adjustable and I can tweak it, but I can't see it giving as good a cut finish as a good forstner. Expensive to try and see.

Gonna try to tag other knowledgeable parties from that old thread:

@John King

@Tony Rozendaal

@Glenn Lefley

@Brian Deakin

@Gord Cameron

Appreciate everyone's input on the best 2 bores for this mechanism's 2 inserts.

I'm looking for current best practices to make the Crushgind mechanism's 2 main bores. I have the notch tool for the "clips", I do not plan to use glue.

From that old thread:

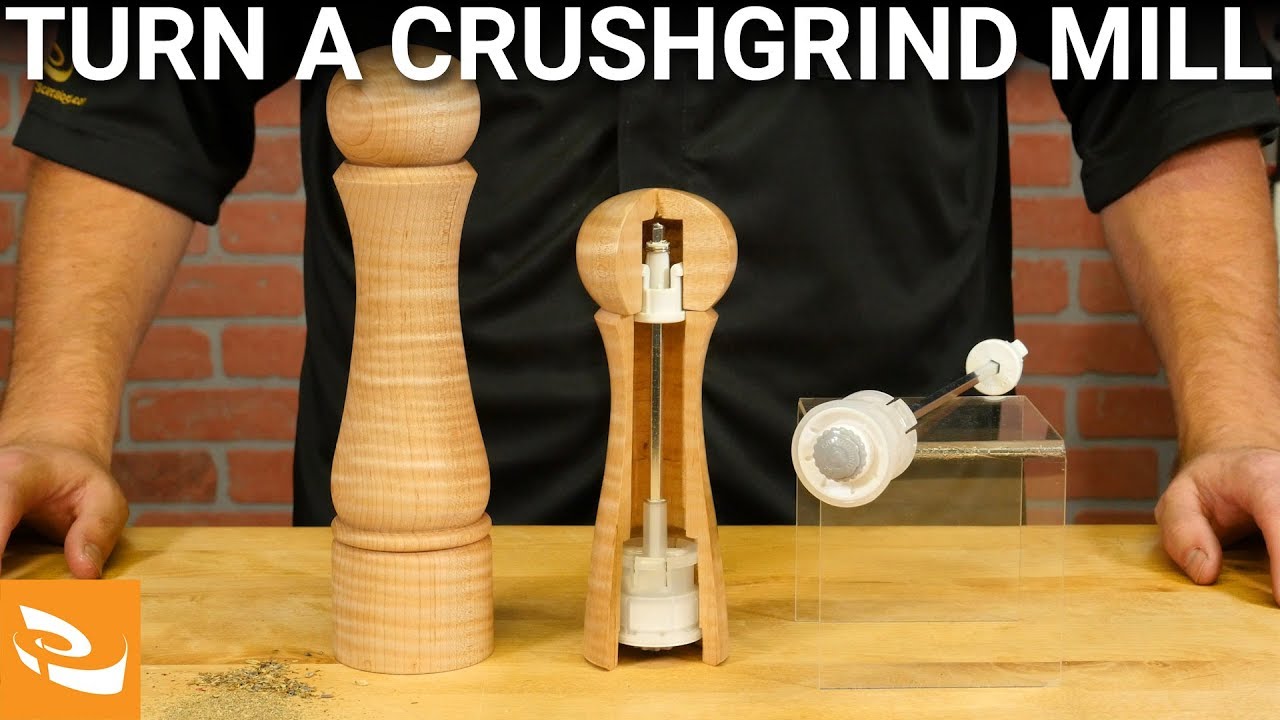

Most, but not all, instructions for making CrushGrind@ mills provided by US suppliers specify 1) a 1⁹/₁₆” diameter hole in the mill body for the grinding mechanism, 2) removal of the spring clips from the grinding mechanism and 3) use of epoxy (or similar) to secure the grinding mechanism in the mill body. These same instructions specify 1) a 15/16” diameter hole in the mill cap for the stopper, 2) removal of the spring clips from the stopper and 3) use of epoxy (or similar) to secure the stopper in the mill cap. One can make a very nice pepper/salt/spice mill using these instructions. But there is a better way! It’s the no epoxy-required way.

The manufacturer’s recommendation for the diameter of the hole in the mill body for the CrushGrind@ mechanism is 38mm (1.496”). I am good with calling that 1½” (1.500”). The manufacturer’s recommendation for the diameter of the hole in the mill cap for the stopper is 22mm (0.866”). I am good with calling that 7/8” (0.875”).

I have a new crushgrind mechanism and their current instructions. I'm trying to optimize the forstner bits I need to do this as I plan to get some higher end Bormax 2/3 forstners.

For the CrushGrind® Shaft instructions, they call for 22mm and 38mm bores to fit the Crushgrind's upper and lower bodies, as John Mentioned in the past. I have a mechanism in hand that I'm measuring. The measurements in the instructions are pretty much the diameter of the respective bodies not including the anti-rotation ribs meant to penetrate wood.

Researching the woodturning community, I see some people/videos using SAE bits that are a 1/16" larger than those recommended bores (15/16 vs. 7/8 and 1-9/16 vs 1-1/2"), and John who posted with certainty to use the size bores in the instructions (7/8" and 1-1/2"). I saw where Brian Horais (RIP) cut the anti rotation ribs off and used 1.5" bores. I'll be using hard woods and I'm concerned those anti-rotation ribs are not going to make that much of an indentation. So, I can press one of these into the 38mm/1-1/2 bore for example, but I'm worried about damaging the mechanism as those ribs aren't going to cut their depth, I don't think.

Anyone have current guidelines and experience with the bores that are best to use? Without using glue.

I've considered using the Woodcut tools Mill to do these. I've encountered more than one person who said they had it but didn't use it preferring the finish of forstners. I like that it is adjustable and I can tweak it, but I can't see it giving as good a cut finish as a good forstner. Expensive to try and see.

Gonna try to tag other knowledgeable parties from that old thread:

@John King

@Tony Rozendaal

@Glenn Lefley

@Brian Deakin

@Gord Cameron

Appreciate everyone's input on the best 2 bores for this mechanism's 2 inserts.

Last edited: