Remove the $$ sign, what lathe would you have?

Last edited:

Robust AB hands down.Remove the $$ sign, what late would you have?

Yes, but that can be fixed with the original premise that $$ is not an issueFloorium is what stops me.

That's a lot of lathe for cantilevering that tiny chuck out so far from the headstock!

That's a lot of lathe for cantilevering that tiny chuck out so far from the headstock!

That is just too clean to be a real shop.

All hat, no cattle.That is just too clean to be a real shop.

That's a Niles pendant chuck in the lathe on the MT2 adaptor they sell.I noticed that. Looks like the two chucks I see are attached to a Morse taper adaptor.

That might have some convenience, but it would be better to use the spindle threads.

=o=

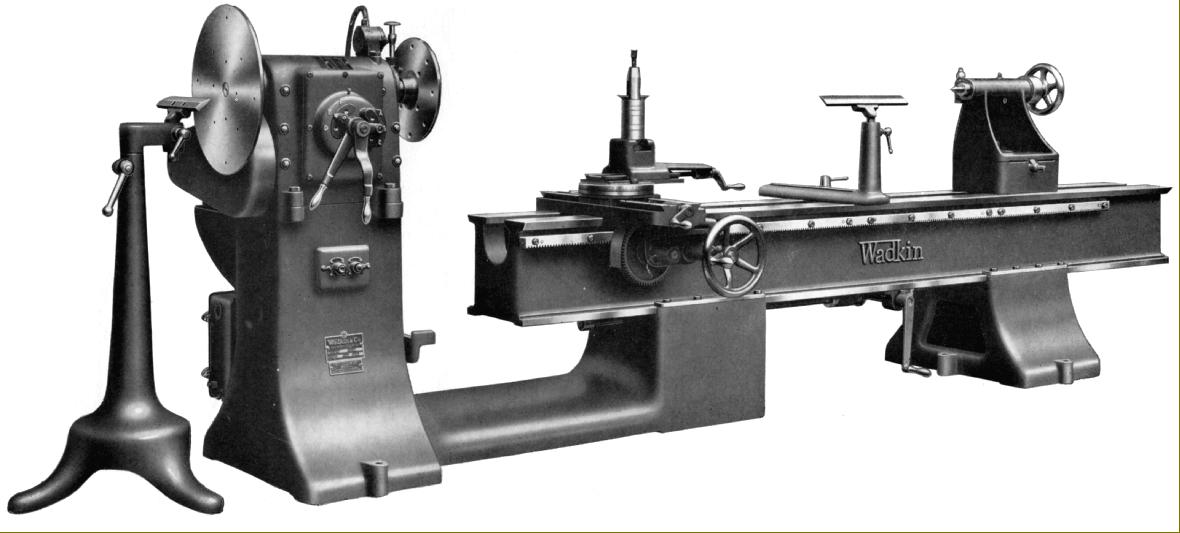

I love the old patternmakers lathes, and Tim's is as fine an example as you'll find. Floorium is what stops me.

One of the old massive Oliver pattern maker lathes would be pretty cool.

That is just too clean to be a real shop.

Floorium would be that element on which one places one's lathe. AKA the floor. Before obtaining a larger (or additional) lathe, one might first need to acquire and install additional floorium.Ok, I'm rather ignorant here: What is floorium?

Floorium would be that element on which one places one's lathe. AKA the floor. Before obtaining a larger (or additional) lathe, one might first need to acquire and install additional floorium.

The lockup is kinda spongy everywhere-I may need to slightly tighten the cams? The tailstock creep as you're cranking down on a big green blank like the 20-poundish 14" wet maple blank I turned this morning is maddening.

Thanks, John-I need to try that asap and I suspect you are correct. Honestly, I could (and should) shut down for a week and just do pm's, clean, dust, organize, grind, etc, etc. If I don't return everything to its proper place, then I spend half my time looking for my 3-inch sanding head or my sanding pad rubber cleaner stick (lost in the shavings, of course).I also have a 3520C... Trying to decipher this. Do you mean the locking of the tailstock in place? I have a bit of tailstock creep on my small Wen lathe. One of the things I've loved about my Powermatic, is that it has ZERO creep, even when I really have to crank the quill in really tight.

Have you ever tried to adjust the clamping plate below the ways? I think you can adjust a nut, probably just a very small amount, to increase the clamping force there. That might help stop any creep you are getting in the tailstock. Worth a try, at the very least, maybe? If it does help, let me know. I suspect over time that nut can probably slightly work itself looser, and that would lessen the clamping force for the tailstock. Same thing happens with my Wen, just a heck of a lot more often, and tightening that nut a bit helps improve the clamping force. The wen ways, apparently, were machined very slightly incorrectly, and they have a very slight taper to them. At the end closest to the headstock, they are very slightly thicker than the end farthest from the headstock, so...I don't think any amount of adjustment will prevent some of the creep I get with the Wen (which is where I turn my pens and other small items.)

The powermatic, however, seems to be perfect and the tailstock clamps down like a giants maw, so I would think you should be able to tune yours and eliminate the creep for your large blanks.

Thanks, John-I need to try that asap and I suspect you are correct. Honestly, I could (and should) shut down for a week and just do pm's, clean, dust, organize, grind, etc, etc. If I don't return everything to its proper place, then I spend half my time looking for my 3-inch sanding head or my sanding pad rubber cleaner stick (lost in the shavings, of course).

Anyway, with our Wens we sort of get what we pay for, eh? They work (sort of), but all the fittings are cheap and rough, with poor tolerances. I have their famous $250 Amazon drill press. It has issues.

So you're saying my walls and door shouldn't rock at 300 rpm with a 10" bowl on my PM3520 in my wooden cabin?Floorium would be that element on which one places one's lathe. AKA the floor. Before obtaining a larger (or additional) lathe, one might first need to acquire and install additional floorium.

would you have?

Nate I got to try one out years back and I could easily stop it with a 1/2" cut and I have never seen a lathe that the bed discolored so quickly from the damp chips.I would love a Serious Toolworks lathe. Almost 1600lbs, 3hp. Integrated mobile base and everything. However, I wish it were available with a stainless bed like the AB. I find the 3520B Powermatic to be a little underpowered when I'm turning big bowls. It's been a while since I've turned anything of size, but I can stop the lathe when doing roughing cuts with a shaving bigger than 1/2".

As long as you're all rockin' together....So you're saying my walls and door shouldn't rock at 300 rpm with a 10" bowl on my PM3520 in my wooden cabin?

Goodness gracious...4HP! What are you looking to turn?Magma Titan 400G with a 4hp motor. I have the Titan 400 with a 3 hp motor and a bed extension which will be my last lathe. The G has cast iron headways which I like. Sliding and pivoting headstock, excellent indexing system and 8 inches of quill travel on the stair stock. 32 inch swing over the headways. Hard to imaging a better lathe.

View attachment 75730