I've had four chainsaws over the last 30 years. I started with a Stihl 025 16"as a homeowner saw for cutting firewood and then added a more powerful Stihl 261 18" a few years later to part out log stumps to make wood bowls on my lathe. I recently bought a Husqvarna 572 XP 28" on a great sale with almost twice the power for cutting up fallen 30" logs. It is so much better than the Stihl 18" at this task. I added little Makita 16" cordless model because it was much quieter than the gas saws for light use in my backyard. I liked the cordless battery operated Makita so much that I sold the Stihl 16" that was still in great shape for $50 less than I paid for it many years before. I chose the Makita brand because I had many other Makita cordless tools with lots of interchangeable batteries and wanted to stay on the same battery platform... and I'm very happy with its performance. It's good to rotate extra batteries through the chargers and keep them at the ready, to keep cutting when the first pair go dead.

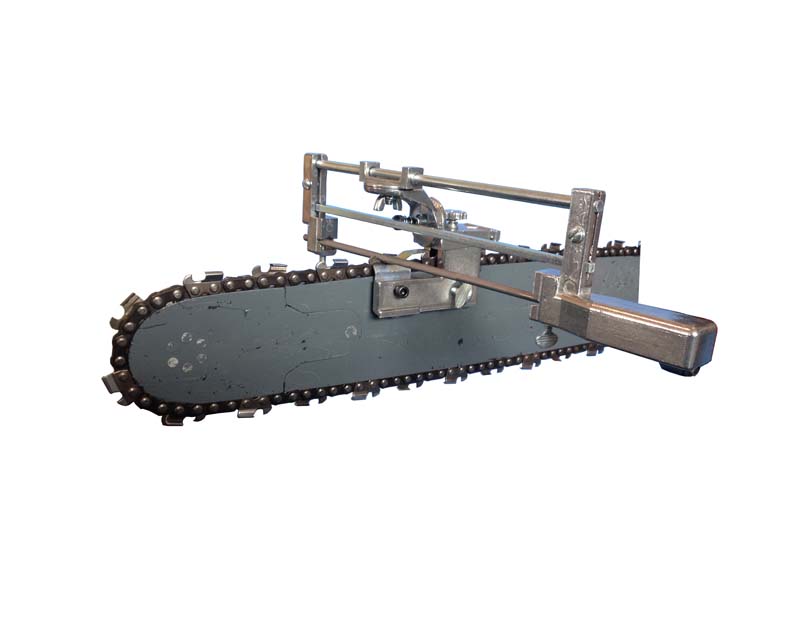

Upon buying each new saw, I added 2 extra chains to swap over when needed. When each chain became dull I struggled to hand sharpen them with a file (and a metal guide) that used up a lot of time. I could never get repeatable results that I was happy with. After several years of unsatisfying results, I started taking my chains to a local shop and paid to get them sharpened... with varying results. After 20 years I got smart and bought a chop saw style Oregon electric sharpener on Amazon with a hand operated vice and 3 pink stone wheels. It has variable tooth angles and offset adjustments for cutting depth and link advancement on the built in vice. The 3 wheels are a flat edged one for kissing the depth rakers, a small diameter one for small chains and large diameter one for the large chains. The Oregon is similar to several other brands but I chose it because it had the best ratings, best customer service and was the cheapest of all brands at the time of purchase. I bolted the sharpener down to a 12' x 12" plywood 3/4" base and then clamped the plywood to my workbench. It became quick to setup, sit in a chair with a face shield on and whip through the collection of chains with amazing results. After a while I switched the setup over to my little hydraulic scissor lift table so I could adjust its height to be comfortable while sitting in a chair with the cutting action at eye level.

I would use up all the chains until dull, either 16", 18" or 28" and then sharpen all of them in the same length one after the other. I discovered a fast way to minimize the overall sharpening time. I setup the 16" chain angle for the right side teeth (sharpening every other one) and rotated the chain around. Then swapped to the next 16" chain sharpening only the right side teeth, then the 3rd chain repeating only the right side teeth. Then I changed the vice angle over for the left side teeth and repeated through all the 16" chains, then 18" and then 28" chains. This was way faster than changing the vice angle twice for each chain size. It was a pleasure to use and the sparks weren't much of a concern. I had to learn to minimize the wheel time in each gullet without blueing the teeth and losing its temper. The most time consuming part was switching the vice angles between chain sizes. The Oregon sharpener came with printed instructions and diagrams that were easy to follow. Competitors chains all had sharpening specs online that I printed out as needed. After seeing the newer CBN sharpening wheels being demonstrated for these chain sharpeners with zero sparks and virtually no tooth blueing at the AAW Symposium in Kentucky this year, I bought one of each size at a nice discount at the WoodTurners Wonders booth from the owner Ken Rizza. These CBN wheels are a big upgrade from the OEM pink stone wheels. Now my nextdoor neighbor wants me to sharpen all his chains too.