New member here and needing suggestions. Bought my first (and only) lathe about 18 years ago. Jet 1442 with reev drive. Used it only a few times before life got in the way and had to put it in storage. About 6 months ago I pulled it out of storage,cleaned it up and have been enjoying it immensely. I retired last month and decided to treat myself to a Robust American Beauty that will be delivered next week. I know the first thing I will need is a chuck. The AB has a 1 1/4x8 spindle and my old Jet is 1 inch. I also have the original assortment of Sorby chisels I started with but am looking at trying some others. Any suggestions or advice is appreciated.

-

February 2026 Turning Challenge: Cookie Jar! (click here for details) -

Congratulations to Chad Eames for "Red Tines" being selected as Turning of the Week for February 23, 2026 (click here for details) -

AAW Symposium demonstrators announced - If the 2026 AAW International Woodturning Symposium is not on your calendar, now is the time to register. And there are discounts available if you sign up early, by Feb. 28. Early Bird pricing gives you the best rate for our 40th Anniversary Symposium in Raleigh, North Carolina, June 4–7, 2026. (There are discounts for AAW chapter members too) For more information vist the discussion thread here or the AAW registration page

-

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Needing chuck/accessories advice

- Thread starter Richard Patrick

- Start date

- Joined

- Apr 27, 2004

- Messages

- 9,324

- Likes

- 6,130

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

you have great lathe coming!!

First thing. Consider taking some classes.

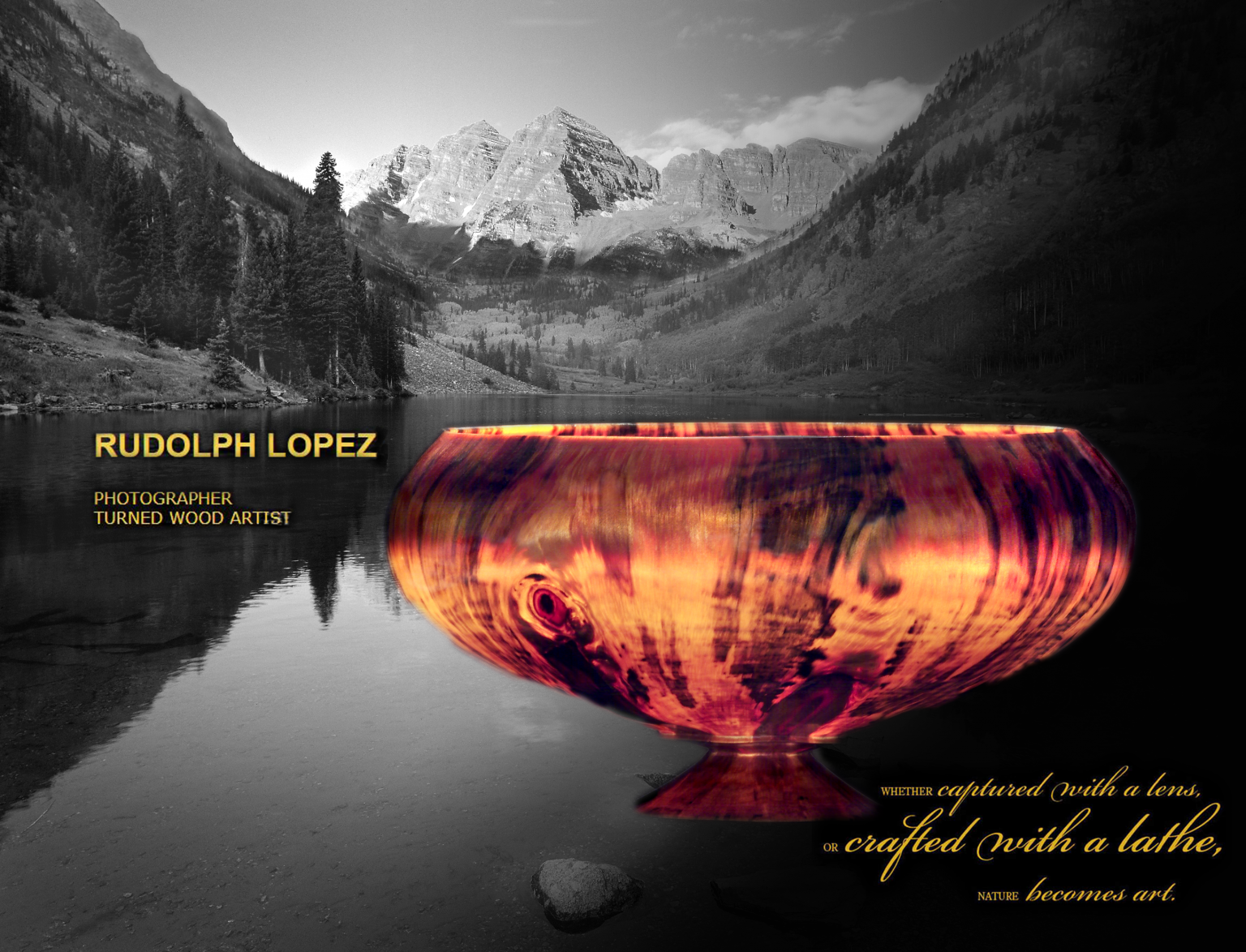

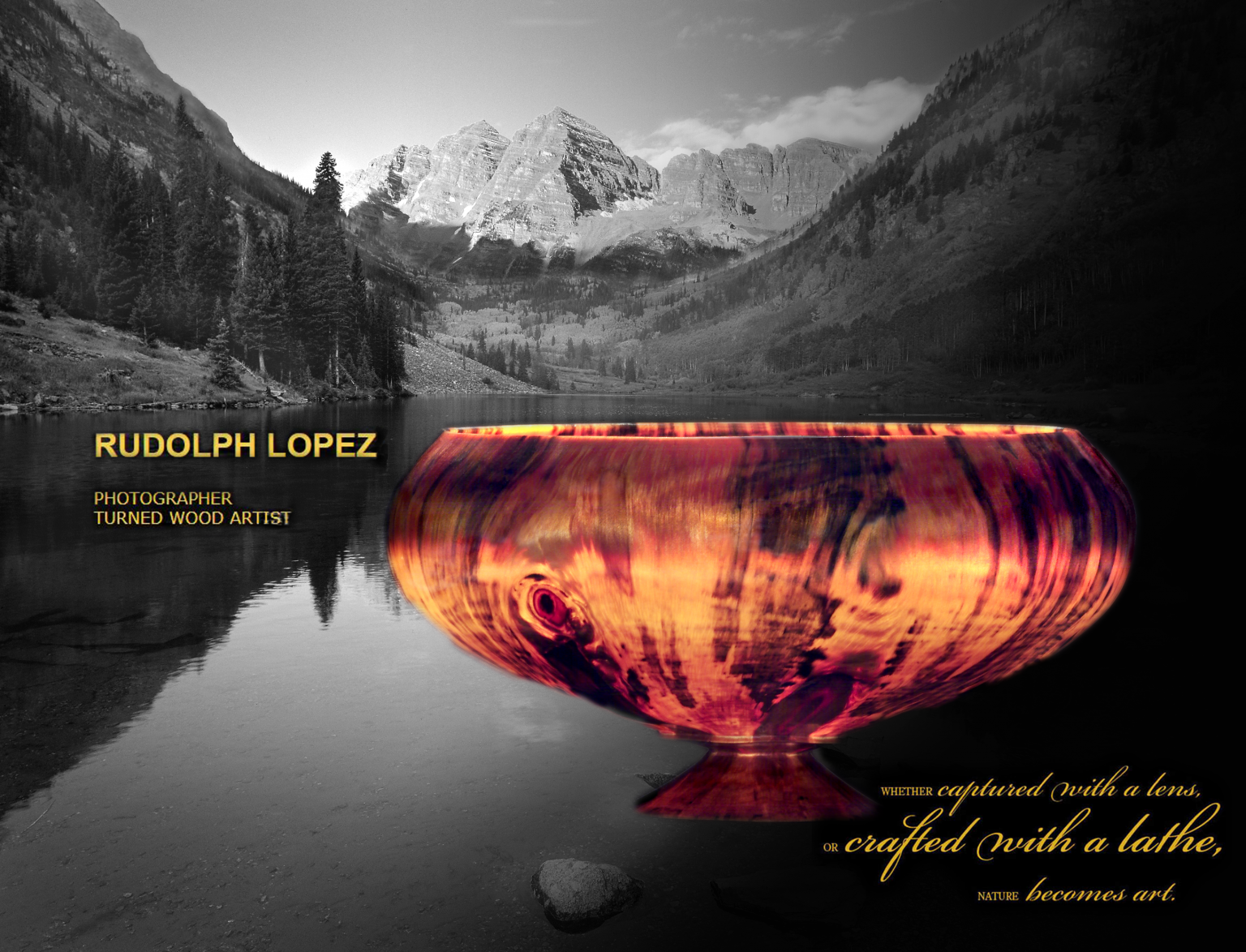

Rudy Lopez in tampa is a excellent teacher. Great 3 day classes. He’ll teach you how to get a lot out of the Robust.

www.rudolphlopez.com

www.rudolphlopez.com

lee sky might be doing some classes he is in plantation. He is in the Aaw dir3ctory.

if you haven’t done so, connect with a local chapter. There may be a closer chapter but I think you are between two

treasure coast chapter meets in Ft pearce

palm Beach chapter meets in West Palm - they have zoom meetings , treasure coast May have them too

First thing. Consider taking some classes.

Rudy Lopez in tampa is a excellent teacher. Great 3 day classes. He’ll teach you how to get a lot out of the Robust.

Homepage - Rudolph Lopez

www.rudolphlopez.com

www.rudolphlopez.com

lee sky might be doing some classes he is in plantation. He is in the Aaw dir3ctory.

if you haven’t done so, connect with a local chapter. There may be a closer chapter but I think you are between two

treasure coast chapter meets in Ft pearce

palm Beach chapter meets in West Palm - they have zoom meetings , treasure coast May have them too

While I love my Vicmarc chucks, I find the Hurricane 125 ( https://www.thewoodturningstore.com...-for-wood-lathes-with-1-1-4-x-8-tpi-spindles/ ) to be of very good quality for a large heavy duty chuck.

For general use, I also like the Nova direct-thread chuck for a "value" purchase. There are those that believe only a Oneway chuck will do...or a Vicmarc. But, I have not found any issue with he Nova chucks. No run-out issues, no durability issues. And - they are be most widely supported brand, with multiple jaws available. ( https://www.teknatool.com/products/chucks/nova-30th-anniversary-supernova2-chuck/ )

For general use, I also like the Nova direct-thread chuck for a "value" purchase. There are those that believe only a Oneway chuck will do...or a Vicmarc. But, I have not found any issue with he Nova chucks. No run-out issues, no durability issues. And - they are be most widely supported brand, with multiple jaws available. ( https://www.teknatool.com/products/chucks/nova-30th-anniversary-supernova2-chuck/ )

They do make an 1-1/4 by 1" threaded spindle adapter that would allow you to use your old chuck on the new lathe. Sooner or later you will want a chuck with the 1-1/4x8 threaded hub that threads directly onto your new lathe spindle. The size and weight of wood blanks you intend to turn will dictate the need for a better quality chuck and the different jaws needed to hold the pieces you want to turn. Most tuners will end up with several different chucks to speed

the process of mounting the projects onto your lathe. A Jacobs drill chuck with a Morse taper that matches your lathe is another valuable tool to use on your wood lathe for various turning and drilling processes on a wood lathe. A set of Collet chucks is another valuable tool to hold spindle type projects on a wood lathe. Over time the average wood or metal lathe user will end up investing more money in accessories that mount to the machine to facilitate various types of turning projects they et involved with. if you plan on turning the same type of items your list of accessories will be minimal if you intend on turning a number of different projects over time, you will end up with a larger variety of accessories for your machine.

the process of mounting the projects onto your lathe. A Jacobs drill chuck with a Morse taper that matches your lathe is another valuable tool to use on your wood lathe for various turning and drilling processes on a wood lathe. A set of Collet chucks is another valuable tool to hold spindle type projects on a wood lathe. Over time the average wood or metal lathe user will end up investing more money in accessories that mount to the machine to facilitate various types of turning projects they et involved with. if you plan on turning the same type of items your list of accessories will be minimal if you intend on turning a number of different projects over time, you will end up with a larger variety of accessories for your machine.

If money is not a problem, you can't go wrong with a Vicmarc VM120. I have several and one VM150.

Roger Wiegand

Beta Tester

The VM120 is available in a direct thread 1-1/4 x 8 version, ie usable without an adapter. This would be, by far, my first choice to pair with your AB. It's a beautiful machine, you will enjoy it! You don't need to worry that some day you will want to upgrade to a better lathe and hence need chucks with inserts.

Thank you to all for your replies. The advice and guidance is much appreciated.

hockenbery, I looked at Rudy Lopez site and seems like it would be a good fit for me to take some classes.

Emiliano and Roger, I took the suggestion you guys made and ordered the VM120 this morning.

I joined AAW a couple of months ago and have been lurking here ever since. I really appreciate the knowledge and experience people share here. Hopefully one day I will be able to contribute!

hockenbery, I looked at Rudy Lopez site and seems like it would be a good fit for me to take some classes.

Emiliano and Roger, I took the suggestion you guys made and ordered the VM120 this morning.

I joined AAW a couple of months ago and have been lurking here ever since. I really appreciate the knowledge and experience people share here. Hopefully one day I will be able to contribute!

Richard, I echo Hockenberry's comments, particularly about Rudy Lopez.

Too late now, but when considering chucks the 1st decision is jaw grip type - there are 3 types dovetail (dt), serrated, and oneway profiled. DT requires the tenon/mortice to be sized closely to the “perfect circle”. Serrated and especially the profiled have a much broader range of size capability, especially in compression (tenon). These jaw types will leave marks/indentations in the wood. The marks aid when remounting a piece, to get it back to the exact location it was before.

All 3 types work, and people have their favorites for various reasons. Food for thought for your next chuck purchase.

All 3 types work, and people have their favorites for various reasons. Food for thought for your next chuck purchase.

Congrats with the new lathe!

As far as chucks chisels etc. you can`t go wrong with Oneway. Wonderfull service in Canadian dollars.

As far as chucks chisels etc. you can`t go wrong with Oneway. Wonderfull service in Canadian dollars.

I have the Vicmark chucks, 4 of the 120's. As for turning tools, I prefer the Thompson and the D Way tools. Both very high quality. Getting lessons is huge since you can learn more in a class in 3 days than you can figure out by yourself in a year or three.... I do have a bunch of mostly bowl turning oriented videos up on You Tube.

robo hippy

robo hippy

I don’t think this is accurate - Vicmarc sells all those jaws as add-ons. (Correct me if I’m wrong)Too late now, but when considering chucks the 1st decision is jaw grip type - there are 3 types dovetail (dt), serrated, and oneway profiled. DT requires the tenon/mortice to be sized closely to the “perfect circle”. Serrated and especially the profiled have a much broader range of size capability, especially in compression (tenon). These jaw types will leave marks/indentations in the wood. The marks aid when remounting a piece, to get it back to the exact location it was before.

All 3 types work, and people have their favorites for various reasons. Food for thought for your next chuck purchase.

Not according to the Vicmarc website. They sell DT and “shark” jaws they refer to as serrated but which have large “serrations” compared to other jaws. Only Oneway has the “profiled” jaws.I don’t think this is accurate - Vicmarc sells all those jaws as add-ons. (Correct me if I’m wrong)

Also the website says the standard jaws are 7 deg DT but the “DT jaws” are 13 deg, pretty confusing if that’s factual.

Roger Wiegand

Beta Tester

This is often said, and I understand that it is undoubtedly true in theory, but I wonder about the day-to-day reality. I've been using a VM120 with DT jaws of several sizes for well over 20 years now all across the range of its gripping capacity (if it fits, it sits!) and find that having a piece come out of the chuck is a vanishingly rare experience, almost always attributable to a flaw, like a soft spot or crack in the wood of the tenon. I've noticed no correlation in failure to how close or far I might have been from a "perfect circle". I often do coring of fairly large blanks with tenons that are considerably larger than the perfect circle, so there doesn't seem to be much of an issue of power transmission.DT requires the tenon/mortice to be sized closely to the “perfect circle”.

With the "8 point" grip it is really easy to re-mount a piece exactly where it was.

It is also often said the DT provides a superior grip to serrated jaws. Same as you, but with serrated and profiled type jaws, used throughout the grip range, for up to 15” hollowing, coring, bowls, the only failures have been due to problems in the wood as you described.This is often said, and I understand that it is undoubtedly true in theory, but I wonder about the day-to-day reality. I've been using a VM120 with DT jaws of several sizes for well over 20 years now all across the range of its gripping capacity (if it fits, it sits!) and find that having a piece come out of the chuck is a vanishingly rare experience, almost always attributable to a flaw, like a soft spot or crack in the wood of the tenon. I've noticed no correlation in failure to how close or far I might have been from a "perfect circle". I often do coring of fairly large blanks with tenons that are considerably larger than the perfect circle, so there doesn't seem to be much of an issue of power transmission.

With the "8 point" grip it is really easy to re-mount a piece exactly where it was.

I do other things, sometimes with other materials, on the lathe for projects around the shop etc. where a straight tenon or mortice grip works much better than a DT grip. The added utility is a plus.

- Joined

- Apr 27, 2004

- Messages

- 9,324

- Likes

- 6,130

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

Like @Roger Wiegand and @Doug Freeman are saying

the perfect circle is the strongest grip but larger diameter openings provide a strong enough grip.

When i use my vicmarc with #2 jaws perfect circle is 48 mm I use this for small stuff to take advantage of the non marring grip.

bowls from green wood I use a 2.5” tenon. Easy for me to size because I’m real got a eyeballing an inch

i cut a tenon 1” from my live center which is 5/8” diameter and I get a tenon close to 2.5” every time.

the ONEWAY profile jaws make a stronger grip a on a 2.5” tenon than dovetail jaws. However the dove tail jaws grip plenty strong enough. I’m much more comforable using a short tenon with dovetail jaws.

the 2.5” tenon when dried for a second turning always has 48mm tenon left in the dried tenon.

for a 48 I measure to a 50mm diameter and cut a 1mm deep groove.

the perfect circle is the strongest grip but larger diameter openings provide a strong enough grip.

When i use my vicmarc with #2 jaws perfect circle is 48 mm I use this for small stuff to take advantage of the non marring grip.

bowls from green wood I use a 2.5” tenon. Easy for me to size because I’m real got a eyeballing an inch

i cut a tenon 1” from my live center which is 5/8” diameter and I get a tenon close to 2.5” every time.

the ONEWAY profile jaws make a stronger grip a on a 2.5” tenon than dovetail jaws. However the dove tail jaws grip plenty strong enough. I’m much more comforable using a short tenon with dovetail jaws.

the 2.5” tenon when dried for a second turning always has 48mm tenon left in the dried tenon.

for a 48 I measure to a 50mm diameter and cut a 1mm deep groove.

Odie

Panning for Montana gold, with Betsy, the mule!

New member here and needing suggestions. Bought my first (and only) lathe about 18 years ago. Jet 1442 with reev drive. Used it only a few times before life got in the way and had to put it in storage. About 6 months ago I pulled it out of storage,cleaned it up and have been enjoying it immensely. I retired last month and decided to treat myself to a Robust American Beauty that will be delivered next week. I know the first thing I will need is a chuck. The AB has a 1 1/4x8 spindle and my old Jet is 1 inch. I also have the original assortment of Sorby chisels I started with but am looking at trying some others. Any suggestions or advice is appreciated.

Wood lathes are very simple machines, and you'll find your old Jet 1442 to be capable of the same quality of work, as your new AB. There is that old saying: "I'm just one tool away from greatness".......and, I believe there are quite a few hobbyists, and even professionals who subscribe to that philosophy. The AB is one of the highest quality wood lathes on the current market, and has an advantage of capacity and convenience, but the quality of your work is entirely up to you!

As well.....creativity is not the product of the tool, but what's contained within your inner soul.

Your Sorby lathe tools are very high quality, and are probably M2 tool steel. Sorby is one of my favorites. Most turners prefer the exotic steels for their lathe tools, but I'm one who enthusiastically believes that M2 has a distinct advantage over the other more expensive exotic steels. They dull faster, but that's not a disadvantage.....it's actually an advantage! You see, because you'll be sharpening more often, you'll actually be keeping the sharpness "in the zone" of useful sharpness more than tools that dull more slowly. That's a concept that many turners have a hard time believing, but in my experience, it does pan out.

As for chucks, I started with one of the original Technatool Nova chucks, sold that, and bought a couple of Vicmarc chucks. Although I feel the Vicmarcs are the highest overall quality built, I ended up selling those, too! I might have kept them, but the serrated jaws weren't available back then. I've since moved on to have four Oneway Stronghold chucks, which I mostly use with serrated jaws. It's an exceptionally strong grip, and as others have mentioned, it's easy to remount using the serrated indentations as a guide for lining it up the same as before.

I only use my Strongholds for roughing purposes, and use waste blocks and center screw chucks for the second turning of dried seasoned bowls. This may effect the choices of those who wish to pursue other methods of mounting, as there are many ways to skin the cat! The way I do things suits me perfectly, but may not be the best for everyone else.

Edit: I forgot to mention that after parting the waste block, I use the Stronghold Jumbo, and Mega Jumbo jaws to grip the rim while the foot is being turned. (Senility......It can happen to you, too! Ha,ha!

-----odie-----

Last edited:

I agree! I have bought several direct-thread Vicmarcs for my AB but, unfortunately, they are not available everywhere. I like having one less mechanical joint and I will never need these chucks for some other lathe (and if I did buy another one it would have 1-1/4 x 8 threads).The VM120 is available in a direct thread 1-1/4 x 8 version, ie usable without an adapter. This would be, by far, my first choice to pair with your AB. It's a beautiful machine, you will enjoy it! You don't need to worry that some day you will want to upgrade to a better lathe and hence need chucks with inserts.

There are a lot of choices for chucks. I started with the Barracuda chucks 10 years ago. I did not like the key for the Barracuda 4 chuck. The Barracuda 2 chuck when I bought it had a squared drive. That has since changed and now have a key similar to the Barracuda 4. I still have my mini Jet lathe and the Barracuda 2 lives there. I bought the Barracuda chucks because of cost. My upgrade was to the Super Nova chucks. A good value, but I hated changing jaws on those chucks. I ended up with 7 Nova and Record chucks. Just because I didn’t like changing jaws. I looked at Stronghold and Vicmarc chucks, but decided on the Axminister brand. They are stainless steel bodies, have 3 tightening locations, direct thread, and the jaws are easy to change, no screws. You do need to buy the jaw slides tat add to the expense, but cheaper than a chuck body. You just crank out one set and crank in another. Axminister has the largest selection of jaws in including the O’Donnell jaws that I use a lot. I sold all my Nova and Record chucks and very satisfied with the Axminister brand.

Regarding tool steels the Thompson are my favorite. M2 is goods, but the exotic steels hold the edge better. You can look at it this way, the second cut with an exotic is as good as the first cut with M2. The third cut with the exotic is better than the fifth cut with M2. When a tool is dull it doesn’t matter the steel.

Everyone has their preference and you will determine what is best for you. The AB won’t make you a better turner, but it won’t make you a worse turner. I have had less expensive lathes, but the AB is just a joy to turn on.

Regarding tool steels the Thompson are my favorite. M2 is goods, but the exotic steels hold the edge better. You can look at it this way, the second cut with an exotic is as good as the first cut with M2. The third cut with the exotic is better than the fifth cut with M2. When a tool is dull it doesn’t matter the steel.

Everyone has their preference and you will determine what is best for you. The AB won’t make you a better turner, but it won’t make you a worse turner. I have had less expensive lathes, but the AB is just a joy to turn on.

We men are strange beings. We chose something because it's expensive, and must be better. I have Nova Titan, and Nova Supernova 2 chucks and jaws. Never had one that wasn't equal to my vicmark in the way it held a piece of wood. I really do not believe I could wear out any of them, or expect them to get sloppy gaps in the moving parts.

For me (when I researched it - might not be 100% as I’m relatively new) it was the hex key chuck and the closed back on the Vicmarc - otherwise would have gone with the Nova.

That’s strange, I own 3 Super Nova II chucks and all of them have hex keys and a closed back. Two of my friends own Nova Titan Iii chucks also with closed backs and operated by a hex key.For me (when I researched it - might not be 100% as I’m relatively new) it was the hex key chuck and the closed back on the Vicmarc - otherwise would have gone with the Nova.

with the exception of the Nova infinity, all nova jaws will fit on any nova chuck.

I think he may be reffering to the older g3 modelsThat’s strange, I own 3 Super Nova II chucks and all of them have hex keys and a closed back. Two of my friends own Nova Titan Iii chucks also with closed backs and operated by a hex key.

with the exception of the Nova infinity, all nova jaws will fit on any nova chuck.

Odie, I understand and generally agree with your statement. However, in this particular instance, the Jet 1442 with Reeves drive and high minimum speed is not nearly as smooth as heavier, VFD lathes. You, in particular, would probably notice the difference and find you can do better work more reliably with a different lathe, especially the AB.Wood lathes are very simple machines, and you'll find your old Jet 1442 to be capable of the same quality of work, as your new AB. There is that old saying: "I'm just one tool away from greatness".......and, I believe there are quite a few hobbyists, and even professionals who subscribe to that philosophy. The AB is one of the highest quality wood lathes on the current market, and has an advantage of capacity and convenience, but the quality of your work is entirely up to you!

-----odie-----

Odie

Panning for Montana gold, with Betsy, the mule!

Odie, I understand and generally agree with your statement. However, in this particular instance, the Jet 1442 with Reeves drive and high minimum speed is not nearly as smooth as heavier, VFD lathes. You, in particular, would probably notice the difference and find you can do better work more reliably with a different lathe, especially the AB.

There are plenty of old lathes.....some very old lathes, that are very smooth operating......but, yes, I get your point, Dean.....

In some cases, I'm sure you would be correct.....and this may be one of them...

-----odie-----

Odie

Panning for Montana gold, with Betsy, the mule!

[snip]...Your Sorby lathe tools are very high quality, and are probably M2 tool steel. Sorby is one of my favorites. Most turners prefer the exotic steels for their lathe tools, but I'm one who enthusiastically believes that M2 has a distinct advantage over the other more expensive exotic steels. They dull faster, but that's not a disadvantage.....it's actually an advantage! You see, because you'll be sharpening more often, you'll actually be keeping the sharpness "in the zone" of useful sharpness more than tools that dull more slowly. That's a concept that many turners have a hard time believing, but in my experience, it does pan out...[snip]

I wandered back to this post today.....and, I still feel exactly the same as I did then..........and I still have not changed my beliefs that very few other turners will agree with it! The reasons will vary, but there are a couple prominent reasons for it. One is that it's simply against what many turners think is "common sense" when they believe a tool that dulls at a much slower rate thereby influences a better experience at the lathe. This is a false concept. Another reason, of course, is because many other turners have invested lots of $$$$ in the exotic steels, and just can't come to terms with the notion that they might not be getting the value they envisioned when they made their large investments in these tools.

There was, of course, a strategic and noticeable difference back in the day when standard lathe tools evolved from carbon steel to high-speed steel.....and, in the scope of things, that made a lot of sense at the time. However, there comes a point when compounding that advantage to the point where it further slows down the rate at which a sharpened tool's cutting edge will dull, actually becomes a disadvantage.....and, I attempted to explain the reasoning for this in the quote above.

-o-

Last edited:

@odie I guess I’m one who doesn’t agree totally with yours statement. I have a variety of tools, M2, Cryo M2, M42, V11, and even the old carbon steel. Some Hurricane, Benjamin's Best, HF, and even Bucks Bros. are brands I have. Not all of them bowl. gouges. When I’m using any them I don’t pay any attention to what steel I’m using. I don’t look to get extra “milage” just because of the steel. When a tool is dull it is dull regardless of the steel. As far as cost, I make my own handles including the aluminum insert and the price is comparable to a handled Sorby. So there is not a huge difference in $$$. One of my favorite is my Benjamin's Best 5/8 bowl gouge. So your theory doesn’t apply to me. Any of these steels will do the job. Just curious do you have any exotic steel tools you have turned with?

Odie

Panning for Montana gold, with Betsy, the mule!

Any of these steels will do the job. Just curious do you have any exotic steel tools you have turned with?

Hi Bill.....

Yes, I've had several in the past, and all but one have been completely used up.

-o-

- Joined

- Apr 27, 2004

- Messages

- 9,324

- Likes

- 6,130

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

I found that the Jamieson gouge made by Thompson has the best flute design for me.

use the Ellsworth grind and often use the flute up shear cut.

The Jamieson gouge makes this cut better than any gouge I have tried.

The Henry Taylor gouge does the flute up shear cut nicely the Jamieson gouge does it better - I believe the better performance for me by the Jamieson is due to the slight difference in flute design and not the different steels.

use the Ellsworth grind and often use the flute up shear cut.

The Jamieson gouge makes this cut better than any gouge I have tried.

The Henry Taylor gouge does the flute up shear cut nicely the Jamieson gouge does it better - I believe the better performance for me by the Jamieson is due to the slight difference in flute design and not the different steels.

What is the flute up shear cut ? Is it the same as the Ellsworth death cut I see people talking about? I guess I don't understand either one. Could you explain?The Henry Taylor gouge does the flute up shear cut nicely the Jamieson gouge does it better - I believe the better performance for me by the Jamieson is due to the slight difference in flute design and not the different steels

- Joined

- Apr 27, 2004

- Messages

- 9,324

- Likes

- 6,130

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

The flute up shear cut - cut with the leading edge of the wing. It is an advanced cut.What is the flute up shear cut ? Is it the same as the Ellsworth death cut I see people talking about? I guess I don't understand either one. Could you explain?

The leading edge of the wing combines a high shear angle and around a 40 degree bevel angle.

Leaves a really smooth surface inside a bowl.

There is a reason every instructor teaching beginners says keep the flute between 9 o’clock and 11:30 or between 3 o’clock and 1:30.

Liam O’Neil taught me this cut in 1995 and David Ellsworth covered it in the class I took with him in 1996.

David showed me more uses of this cut.

It’s an easy cut to master with instruction. Hard to impossible to teach it to yourself.

People who try it on their own call it the death cut because it is easy to get horrible catches using trial and error.

Peopl that get good instruction call it a shear cut.

One great thing about this cut is it can be used starting at the rim on an interrupted cut natural edge bowl

On a flat rim bowl just about impossible to start at the rim so I roll into the flute up cut an inch below the rim.

I like the Ellsworth grind for this cut. This is probably a Henry Taylor gouge. A Jamieson will look similar from this angle.

Here I start to cut a NE bowl rim to thickness. I feel for the edge and make a cut.

One cool thing is on an open bowl shape you can see both the outside and inside wall you just cut.

This lets you get a really even wall visually down to the lower rim

Thanks for the excellent description. I have a Jamieson gouge with a grind like the one in your picture. This is what I thought it was but wasn't sure. Now I have to find someone who knows how to do it to instruct me.The flute up shear cut - cut with the leading edge of the wing. It is an advanced cut.

The leading edge of the wing combines a high shear angle and around a 40 degree bevel angle.

Leaves a really smooth surface inside a bowl.

There is a reason every instructor teaching beginners says keep the flute between 9 o’clock and 11:30 or between 3 o’clock and 1:30.

Liam O’Neil taught me this cut in 1995 and David Ellsworth covered it in the class I took with him in 1996.

David showed me more uses of this cut.

It’s an easy cut to master with instruction. Hard to impossible to teach it to yourself.

People who try it on their own call it the death cut because it is easy to get horrible catches using trial and error.

Peopl that get good instruction call it a shear cut.

One great thing about this cut is it can be used starting at the rim on an interrupted cut natural edge bowl

On a flat rim bowl just about impossible to start at the rim so I roll into the flute up cut an inch below the rim.

I like the Ellsworth grind for this cut. This is probably a Henry Taylor gouge. A Jamieson will look similar from this angle.

View attachment 62418

Here I start to cut a NE bowl rim to thickness. I feel for the edge and make a cut.

View attachment 62420

One cool thing is on an open bowl shape you can see both the outside and inside wall you just cut.

This lets you get a really even wall visually down to the lower rim

View attachment 62419

I do tend to think of it as a peeling cut, very similar to what you can do with a skew. You are rubbing the bevel of the wing on the cut. The problem and cause of the huge catch is if you come off of the bevel, even a tiny bit. You have a sharp edge, with no support, and it is pointing into the spinning wood. This also happens to be similar to the catch that most get when using a SRG on bowls. It is controlable as long as you don't come off of the bevel. SRGs can be used on bowls, but too many other tools do a far safer job. I do not use the flute up shear cut.

robo hippy

robo hippy

Thanks for the excellent description. I have a Jamieson gouge with a grind like the one in your picture. This is what I thought it was but wasn't sure. Now I have to find someone who knows how to do it to instruct me.

www.turnawoodbowl.com

He has many free articles and videos, both on his site and on Youtube. He also has some paid courses ($80-100), including one on tool sharpening. His go-to gouge is the 55 degree Ellsworth grind.