I usually get mine from WTTools.

https://www.wttool.com/search/go?w=bits

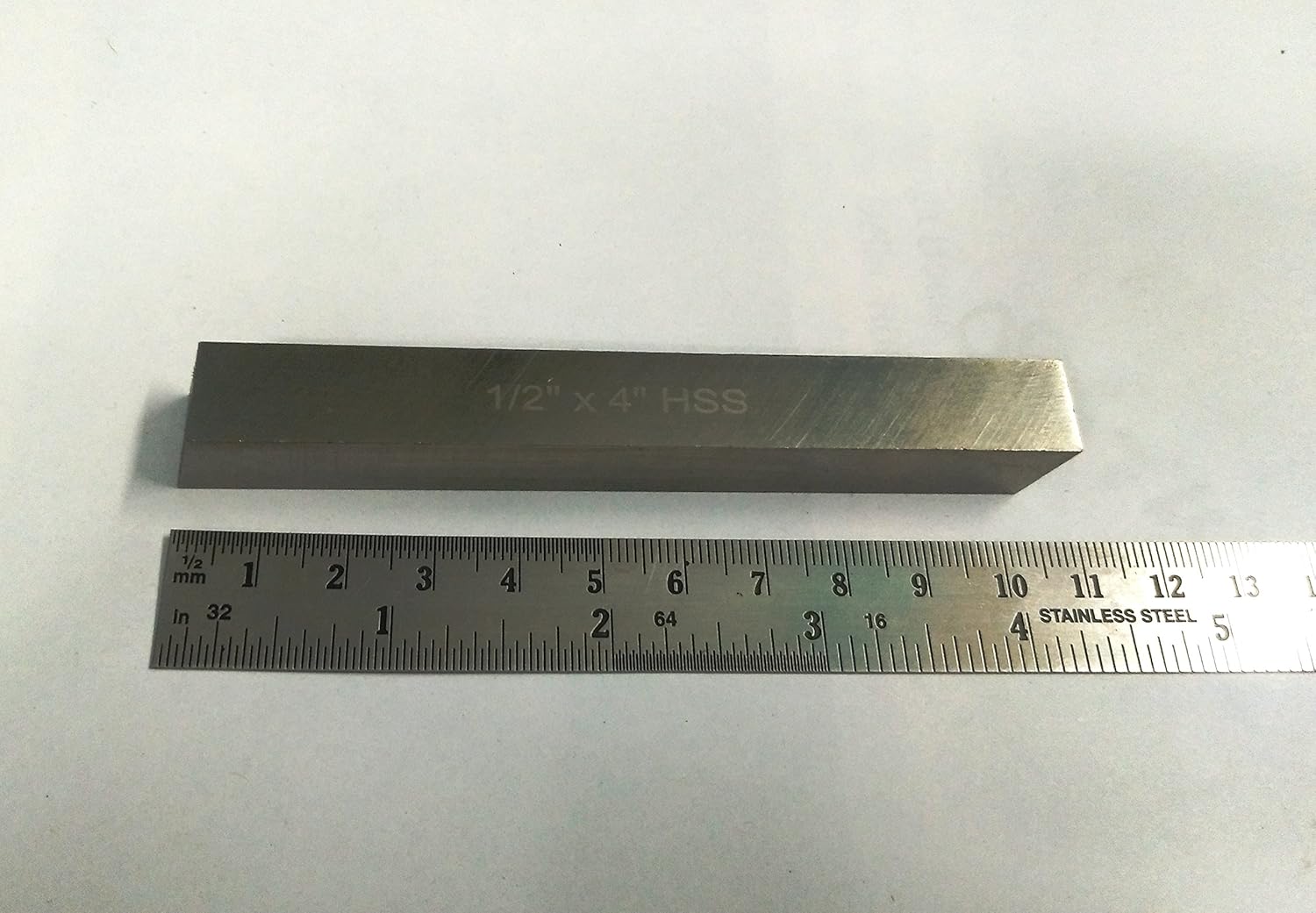

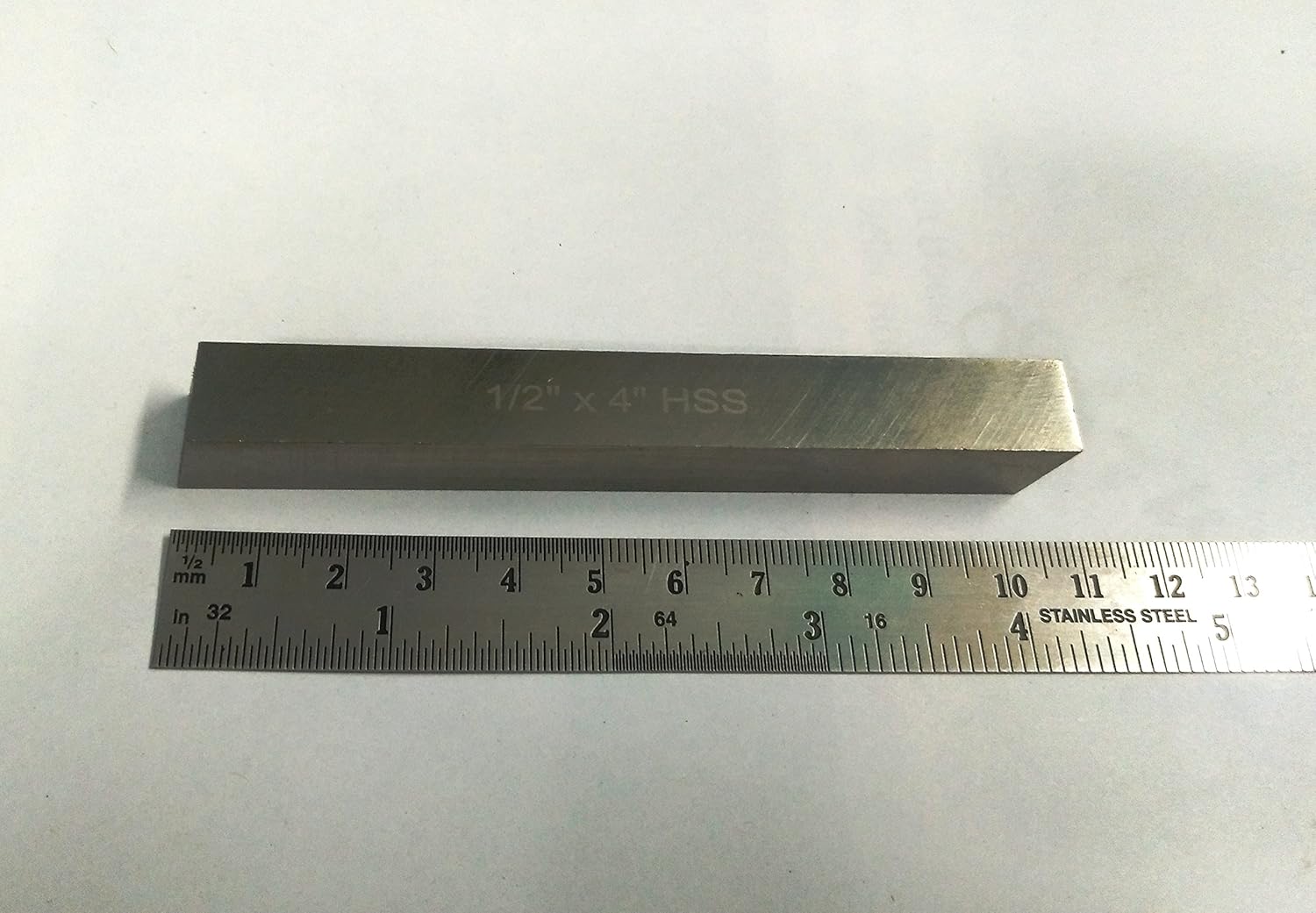

They are under "bits"; the 1/4, 3/8, and 1/2 are all they normally have in 8" length.

The 1/2" standard M2 is usually $9 or with 5% cobalt $15.

Thanks again, Michael.......I ordered 5 of the 1/2" x 1/2" x 6" standard M2 tool bits.....(too bad they're not available in longer lengths).....I can use about 2" of the length before they get a little too short for my purposes. That makes about 10" of usable length.....and still MUCH cheaper than buying the Sorby heavy duty scrapers I had been using for this.

Odie I think that a more derailed description of what you want to do would help

Bill......I'm using them as detail shear scrapers, using my homemade handles. For these, I use manually raised burs exclusively. Visualize this: With the 1/2" x 1/2" square tool bit, and using it as a shear scraper, the weight and fulcrum of the tool is closer to the cutting edge......I think that's an important consideration to contemplate, as well as put into physical action.

I've been so financially handicapped that, over the years, I've made hundreds of home made tools and jigs......Being so short on budget cash can be viewed as a blessing, as well as a handicap......depends on how you look at it!

I haven't had the luxury of being able to throw money at my turning endeavors, so for many of my turning tasks, I've had to improvise, with a little added "fly at the seat of my pants" creativity!

(In the final analysis, it does tend to make the overall learning process take on a whole new perspective that isn't apparent when you just buy tools and jigs that are pre-made for someone else's purposes!

)

(BTW, Bill......hope you are making progress, and will be making shavings again very soon!

)

-----odie-----