John-If you ever get the chance, go see one. It is art expressed as an exquisitely engineered, solid machine. The tool-rest post id is 40mm, and it locks up like Fort Knox. I can't wait to give one a spin when Tim gets his set up and running. He said if price were no object. For me it is, so I will never own one (or a fully blinged-out Platinum Tundra either, but a man can dream).

-

January 2026 Turning Challenge: Turned and Bent! (click here for details) -

Congratulations to Phil Hamel, People's Choice in the December 2025 Turning Challenge (click here for details) -

Congratulations to Ric Taylor for "Black Ash Burl" being selected as Turning of the Week for January 26, 2026 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dream lathe

- Thread starter Webb Willmott

- Start date

Jon, I have a PM 3520C and I agree with you on the design of the tailstock. I think PM designed the tailstock with a slant towards the back in order to increase the overall distance between centers. This extra distance (about 2") when the tailstock is hanging off the end of the lathe, has come in handy for me when I turned several baseball bats for my grandsons.Some are things I've come to like, SINCE buying a Powermatic (which is a good lathe, but its not my dream lathe. ;P ) One of these is the strait up and down nature of the headstock and tailstock. The Powermatic tailstock design, is angled...so that the front of the quill ends up back-set from the front bottom edge of the tailstock (which itself, is even further backset a bit, because of the size of the round clamping plate underneath the ways). The banjo then is also rather wide, with the tool rest front-oriented. This means that between the backset of the front of the quill, plus the width of the banjo, you have to extend the quill quite a bit just to contact the wood. The quill is stable, but, so much of its potential extension is just wasted over empty space. That made me notice and appreciate the design of the American Beauty all that much more, as you don't have to waste any quill extension that way.

That step back may be handy for baseball bats, but it requires running the quill out excessively for short things (and much of what I've turned in recent years is not long although often wide. It's an aggravation. I turn on a lot of 3520Cs for demos and teaching/taking classes. I don't own one (I did have a 3520B, which did not have that unfortunate design 'feature' -- given a choice between a B and a C, I'd leap for the B).Jon, I have a PM 3520C and I agree with you on the design of the tailstock. I think PM designed the tailstock with a slant towards the back in order to increase the overall distance between centers. This extra distance (about 2") when the tailstock is hanging off the end of the lathe, has come in handy for me when I turned several baseball bats for my grandsons.

Surprised the Oneway 2436 isn’t mentioned above. It my dream lathe and it’s sitting in my shop right now.

As I mentioned to Jon, and I agree with you as well, that the PM tailstock is agravating and it does put stress on the quill during normal turning. I was only pointing out what "may" be PM's design ratrional for the slant back. I wasn't trying to defend their tail stock design.That step back may be handy for baseball bats, but it requires running the quill out excessively for short things (and much of what I've turned in recent years is not long although often wide. It's an aggravation. I turn on a lot of 3520Cs for demos and teaching/taking classes. I don't own one (I did have a 3520B, which did not have that unfortunate design 'feature' -- given a choice between a B and a C, I'd leap for the B).

I'm perfectly content with what would be described nowadays as the mid-sized lathe realm. I just didn't need the 24"x53" my old Vicmarc VL300 provided me. I'm thrilled by the high quality results I get from my 16" Vicmarc VL200 shortbed, and my Oneway 1224 with bed extension. I can turn tiny stuff, dinner plates, big popcorn bowls, baseball bats, vases, etc. no problem. If I had to downsize, the VL200 would be the one to go, pretty rare when I push its limits anymore.

Surprised the Oneway 2436 isn’t mentioned above. It my dream lathe and it’s sitting in my shop right now.

It's one of the finest out there, for sure.

A Sweet-16. It meets all the criteria I’m looking for and one I can grow old with.

Something big with a pivoting headstock and remote pendant.

Bought my dream lathe 13 years ago next month - Robust AB. 13 years down the road and it still runs like new and makes me grin just walking into the shop. It has done everything I’ve asked of it - big or small. Not a single component has failed, worn out or otherwise ceased to function, and it looks like that’s going to continue for the rest of my turning life.

Was it expensive? Oh yeah - took a while to save up. Was it worth it? Oh yeah - I’d do it all over again given the chance.

Was it expensive? Oh yeah - took a while to save up. Was it worth it? Oh yeah - I’d do it all over again given the chance.

If powered by a VFD, motor output power diminishes directly proportional to speed. And torque does not increase; it remains constant for practical purposes from about 10% speed (can go lower with sensorless vector drive) up to rated speed. So a 4hp rated motor will produce roughly 1hp at quarter-speed. That's why seemingly large three-phase motors tend to be used on lathes.Goodness gracious...4HP! What are you looking to turn?

Tim

I think the "dream" lathe for anyone depends a lot on what they like to turn or would like to turn.

Since I quickly dumped my first lathe almost 25 years ago (the deeply flawed clone of the old Craftsman monotube) and bought a "full sized" lathe, my dream lathe has been the one I see when I turn on the shop lights, whatever it is.

I have little desire to turn big bowls, green wood (too easy), incredible hollow forms - been there, done that. I'd be the worst production turner ever, bored to death after the 2nd piece. I don't turn to sell. Those who love such things might well benefit from one of the amazing lathes available today. I'm am glad others are keeping the lathe makers in business! (I try to keep the tool makers in business)

I love to turn mostly smaller things from dry wood, the harder the wood the better. I love experimenting with form and detail, the more unique the better. I usually make a variety of sketches before I mount wood on the lathe. I never get in a rush. I love doing demos and teaching, especially beginners.

A dream lathe for me is one of sturdy construction that spins with no mechanical slop when I turn it on, has adjustable speed and reverse, will accept all my existing chucks and accessories, and has a sufficiently long bed. I don't need Herculean power since sharp tools and patience can always replace brute force, and arguably with less potential drama.

The Jet1642 I bought in the early 2000s was perfect for me. Building a big stand-alone shop with central heat and air made turning even more enjoyable. Adding a second 1642 helped with teaching and special projects. Replacing one of those Jets with a used PM3520b with a bed extension embedded me firmly in dream land.

And even the most amazing lathe in the world is not much fun without wood. Having a huge supply of dry blanks in adjacent rooms, in a variety of sizes, and of a multitude of species, is beyond priceless.

Life is good.

JKJ

Since I quickly dumped my first lathe almost 25 years ago (the deeply flawed clone of the old Craftsman monotube) and bought a "full sized" lathe, my dream lathe has been the one I see when I turn on the shop lights, whatever it is.

I have little desire to turn big bowls, green wood (too easy), incredible hollow forms - been there, done that. I'd be the worst production turner ever, bored to death after the 2nd piece. I don't turn to sell. Those who love such things might well benefit from one of the amazing lathes available today. I'm am glad others are keeping the lathe makers in business! (I try to keep the tool makers in business)

I love to turn mostly smaller things from dry wood, the harder the wood the better. I love experimenting with form and detail, the more unique the better. I usually make a variety of sketches before I mount wood on the lathe. I never get in a rush. I love doing demos and teaching, especially beginners.

A dream lathe for me is one of sturdy construction that spins with no mechanical slop when I turn it on, has adjustable speed and reverse, will accept all my existing chucks and accessories, and has a sufficiently long bed. I don't need Herculean power since sharp tools and patience can always replace brute force, and arguably with less potential drama.

The Jet1642 I bought in the early 2000s was perfect for me. Building a big stand-alone shop with central heat and air made turning even more enjoyable. Adding a second 1642 helped with teaching and special projects. Replacing one of those Jets with a used PM3520b with a bed extension embedded me firmly in dream land.

And even the most amazing lathe in the world is not much fun without wood. Having a huge supply of dry blanks in adjacent rooms, in a variety of sizes, and of a multitude of species, is beyond priceless.

Life is good.

JKJ

Last edited:

With my current set up, I turn bowls on my Vic 240. I core on my Robust Liberty. I sand on my Beauty. For spindles, which I don't do many of, I go to either the Robust or the Vicmark. I do have 2 mini lathes dedicated to small boxes and threaded boxes.

robo hippy

robo hippy

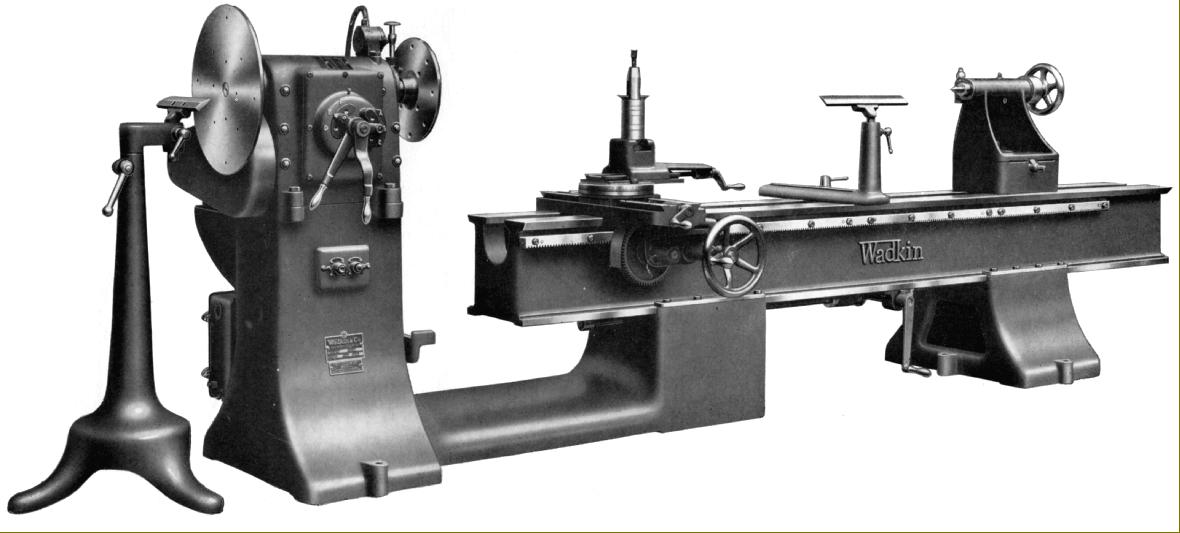

Would I have... Having a lathe is different from using it daily. Because of this, I want a Wadkin RU. With infinite money, I would refurbish it and modify it with some modern features, such as a VFD. How much would that weigh?

I would be happy with an RS10. And if we're spending dream-money, I would have an AB or Vicmarc in there too. I would be down one wife though, with all that temptation.

No doubt about the ultimate dream lathe for quickly creating turnings.

A patternmakers lathe with a power feed carriage with tool rests for hand turning too. Not sure if anybody still makes them. Recently there was a locally advertised Oliver patternmakers lathe capable of 12' length with two carriages, one for each end of the turning. Plus outboard turning capacity of 4 feet. Went dirt cheap because of its length.

The ultimate machine for making bowl-like items would be a CNC milling machine. But this might not fit the description of a lathe.

A patternmakers lathe with a power feed carriage with tool rests for hand turning too. Not sure if anybody still makes them. Recently there was a locally advertised Oliver patternmakers lathe capable of 12' length with two carriages, one for each end of the turning. Plus outboard turning capacity of 4 feet. Went dirt cheap because of its length.

The ultimate machine for making bowl-like items would be a CNC milling machine. But this might not fit the description of a lathe.

Hager KDFE1800Remove the $$ sign, what lathe would you have?

My old Vicmarc VL100 mini lathe. 10"x15" capacity, I built it up on a Jet mini lathe stand and powered it with a new 3/4hp DC Leeson and Minarek drive. I sold it to make room for my friend's Vic VL200 when he downsized. For a few minutes, I owned the whole family- VL100/200/300. Only the 200 remains with me. I tracked down the VL100 a year ago to see if I could buy it back. It was sold to yet another loving home, and they aren't parting with it. I wish I'd kept it, 10 times better than every clone that came after it. Don't need it, just wanted it back if possible. The heart wants what the heart wants.

I have a Record Power Envoy and am very happy with it.

If you take away the $$ restriction I would say I would spring for a Robust AB, with some fun bells and whistles.

If you take away the $$ restriction I would say I would spring for a Robust AB, with some fun bells and whistles.

Tailstock swing-away is an amazing thing. I'd thought to just heave-ho the tailstock out of the way when I'd originally planned on getting a Nebula, so getting swing away when I ended up with my Harvey T-60S was an unexpected gift. Bonus points for the mechanically simple design which creates a purely horizontal swing plane. It's nearly a one finger operation to swing it in or out of the way.Oh, absolute best tailstock mechanism for getting it out of the way, Robust, by a long shot!

If I were starting from the ground up in this craft, the Record Power lathes would be a serious contender for my dollar.I have a Record Power Envoy and am very happy with it.

If you take away the $$ restriction I would say I would spring for a Robust AB, with some fun bells and whistles.

Robust AB is the finest woodworking machine I ever owned albeit for a short time. The machining is impeccable and when I say impeccable I mean no shims are required. And Brent at Robust is absolutely fantastic in the customer service department.

I would agree with others - Robust American Beauty. I always wish that I had bought the AB instead of the Powermatic 3520, but being in my 70's it was hard to justify more than double the cost for the Robust lathe. I have never found anything to be dissatisfied with on the Powermatic except the paint job on the lathe which chips off constantly in places that I don't even work near. Robust's lathe would look like new at this point while my Powermatic looks like it's way older than the 3+ years I've owned it. Otherwise, both great lathes.

have to agree - it was a stretch when I bought it 13 years ago - but when I considered that I would be retiring in a couple of years, I took the leap while I could make up the difference. It has been a flawless piece of equipment ever since and shows no signs of slowing down or wearing out. Still get a grin on my face everytime I walk into the shop...gotta love the Beauty.Robust AB is the finest woodworking machine I ever owned albeit for a short time. The machining is impeccable and when I say impeccable I mean no shims are required. And Brent at Robust is absolutely fantastic in the customer service department.

My Nova DVR3000 is 23 or 24 years old and still looks like new. My Powermatic will be 20 years old this October (I have a picture of it still boxed laying on the shop floor and not put together because I was going to my first symposium, Turning 2005) and it is very clean considering how many pros have used it (sometimes a pro would do something to my lathe that I would never do). My Nova Mercury and the little Vicmarc are the oldest of my lathes because I bought them from my club and they had been with the club since it started so they were older than the club as they were donated and I believe they are both older than 26 years. The Vicmarc has a very low serial number from I think from Craft Supplies. My Jet 16" lathe is about 17 years old and my Nova Neptune is about 3 years old. I take good care of all of them. They are all cast iron. I do have 1 other and that is a 12" 3/4 hp cast iron lathe from Vevor as I could not believe I could buy a lathe like that from China via Los Angeles for $285.95 delivered. It was delivered and I have made this my pen lathe and it works just fine, it is about 5 years old.

I bought my Robust AB a few months ago and love it. When ordering it spoke with Brent about turning height since I like to turn a bit lower using long handled tools riding my hip (not great for spindles but I don’t do a lot of that) and it shipped to me at the precise height we discussed . . . it’s the little things that sometimes matter.

after months of studying and researching I finally bought my dream lathe. Laguna 15/24. For what I turn and want to turn this was the perfect lathe.

Hi Tom, Brent is a fantastic listener. As a direct result, his lathe and accessories are so well received by the turners.

I almost gave up looking for this thread.... 6 pages back, and at the limit of my attention span.... I REALLY wish all manufacturers would go to the wedge system for tool rests, like on the Robust and PM 3520C. with both my mini lathes and my Vicmark, the tool rest REALLY has to be tightened down to get it to stay in place, even with light cuts. Considering that the handle on most banjos are cheap pot metal, and the set screw is a hardened metal, this is going to wear out, not if, but when. That wedge system is the best I have seen. I remember on my 3520A, I had a T made from a machinist friend where the lever slipped through like most bench vices. This did work, and didn't mark up the posts. I think I had a second one made for "added" hold. To date, the wedged system seems to work best. If I remember correctly, the first Robust banjos had a cut groove in the vertical part of the banjo so, at least in theory, when tightened up, the sides would pull together a bit and really lock in the tool rest height. I really don't like the tool rest slipping when I turn..... ARGH!!!!

robo hippy

robo hippy

Would love an AB but my 3520B does everything I ever ask of it. This picture was taken the day I brought it home, it was 9 years old at that time

I could drool if I let myself. However, like you, the 3520B does anything I want, more than that even. As sturdy as the Rock of Gibraltar, plenty of adjustment, power, precision, doesn't complain when I abuse it, keeps going like the Energizer Bunny. Long and thin spindles, green bowls, miniatures, platters. It thrives on lots of light and climate control.

I had Jet1642s and turned and learned and taught. When I found a reasonable used 3520b with bed extension and a lot of extras I drove to Maryland with a trailer to bring it home. Put one of the Jets in storage, eventually gave the other to a friend. Added a bunch of Robust rests, lots of chucks, plenty of tools for it to make friends with - most within arm's reach or just a couple of steps away. Life is good!

Ah, yours looks cleaner than mine. Still that clean?

I clean the shavings off of mine on occasion.

Hey, I don't have that fancy logo plate or the racing stripes. I think I'll live.

I have several friends with the "A" model and they love them too.

JKJ

Bought my dream lathe at the AAW Symposium when it was in Pasadena, CA. Roughly 20+ years ago.

I called up Oneway and checked to see if they were bringing out a truck load of lathes to use at the symposium. I think I got the last one on the truck. 2436 with a 3hp motor, short extension for the outboard end and an extra banjo for the outboard.

I have used it this whole time with only a minor problem with the stop switch quitting. Easy, cheap fix after 20 years of use. I use the lathe almost every day and will keep using it until one of us quits. I think I will be the first to go.

I have tried the AB Robust and it is a nice lathe, but I was used to the Oneway and not everything was in the same place. Kept knocking into things.

Love my Oneway 2436.

I called up Oneway and checked to see if they were bringing out a truck load of lathes to use at the symposium. I think I got the last one on the truck. 2436 with a 3hp motor, short extension for the outboard end and an extra banjo for the outboard.

I have used it this whole time with only a minor problem with the stop switch quitting. Easy, cheap fix after 20 years of use. I use the lathe almost every day and will keep using it until one of us quits. I think I will be the first to go.

I have tried the AB Robust and it is a nice lathe, but I was used to the Oneway and not everything was in the same place. Kept knocking into things.

Love my Oneway 2436.

No, it doesn't look like that now, I've added about 300 lbs of ballast to it and have it properly slimed up. Also added a remote control box so no fear of reaching across the line of fireI could drool if I let myself. However, like you, the 3520B does anything I want, more than that even. As sturdy as the Rock of Gibraltar, plenty of adjustment, power, precision, doesn't complain when I abuse it, keeps going like the Energizer Bunny. Long and thin spindles, green bowls, miniatures, platters. It thrives on lots of light and climate control.

I had Jet1642s and turned and learned and taught. When I found a reasonable used 3520b with bed extension and a lot of extras I drove to Maryland with a trailer to bring it home. Put one of the Jets in storage, eventually gave the other to a friend. Added a bunch of Robust rests, lots of chucks, plenty of tools for it to make friends with - most within arm's reach or just a couple of steps away. Life is good!

Ah, yours looks cleaner than mine. Still that clean?

I clean the shavings off of mine on occasion.

View attachment 79330

Hey, I don't have that fancy logo plate or the racing stripes. I think I'll live.

I have several friends with the "A" model and they love them too.

JKJ

Roger Wiegand

Beta Tester

Things that make you go hmmmm.............The above post was one May 21st. On August 13th, Odie posted something about a new lathe on it's way. Seems like the VL240 dream came true.My dream lathe would be a heavier Robust Sweet 16 with a swivel headstock!

The Powermatic 3520c and Vicmarc VL240 are also very appealing......with a few changes!

=o=

Great minds must think alike because I picked up my dream Sweet 16 when I was in Wisconsin to see Airventure (Oshkosh) in July so there were 2 of us that had a dream come true.

I only flinched once when I wrote the check. I was forturnate enough to recently sell a "hobby" sports car that wasn't getting used very often, so I traded hobby dollars and bought the lathe. I considered it a win/win since the lathe doesn't require insurance or have maintenance cost.

I look hard and long at other lathes. I excluded price and focused on what I wanted. All lathes had some of what I wanted but the Robust Sweet 16 had them all and some features I really liked but where not on my "I want" list. I know I would have been happy with any of the lathes and everyone of them would have exceeded my abilities however I wanted what I wanted and focused on that.

And as Ringo sings......You're sixteen, you're beautiful, and you're mine......

Looks like a Joyner Off Center Jig from NilesThat's a lot of lathe for cantilevering that tiny chuck out so far from the headstock!

I had a small lathe originally then my first good sized lathe was a Jet 1442 with a bed extension. Although it was rated as industrial and saw me transition from an enthusiastic hobbyist to a full time professional, I pretty much wore it out. I had good capacity though and a new lathe with similar or greater capacity would have been out of my budget at the time. I went old-school with a Wadkin RS8 pattern makers lathe. You get a lot of cast iron for your money with these old machines. It was 75 years old this year (built in 1950) and I gave it a VFD for its birthday present. It does everything I ask of it and never lets me down.

Lathe tour here if interested (on my new YouTube channel)

Richard

Lathe tour here if interested (on my new YouTube channel)

Richard

I have a Laguna 2436 and really like it, but I bought it more as a “budget” lathe (if you can call $3000 “budget”). I’ve turned on a PM 3620B and to me it felt like it was a little higher quality than my Laguna (smoother tailstock and banjo movement, a little more solid-feeling) but not significant and for the cheaper price and larger swing I’m happy with my Laguna. I’ve turned 23.5” wet blanks and regularly core aggressively and the Laguna has stood up well without any issues.

That being said, someday when I win the lottery I would like to upgrade and from all I’ve read and heard from other turners, my dream lathe would be either the Robust AB or the Vicmarc VL300. I’ve never had the opportunity to turn on either of them but I’m wondering if others have turned on both of them, which lathe they prefer and why. That way I can narrow my dreams to just one lathe!!

Tom

That being said, someday when I win the lottery I would like to upgrade and from all I’ve read and heard from other turners, my dream lathe would be either the Robust AB or the Vicmarc VL300. I’ve never had the opportunity to turn on either of them but I’m wondering if others have turned on both of them, which lathe they prefer and why. That way I can narrow my dreams to just one lathe!!

Tom

Now that's cool! Keep it running! I knew a guy who had rehab'ed an ancient Oliver. What a beast that was.I had a small lathe originally then my first good sized lathe was a Jet 1442 with a bed extension. Although it was rated as industrial and saw me transition from an enthusiastic hobbyist to a full time professional, I pretty much wore it out. I had good capacity though and a new lathe with similar or greater capacity would have been out of my budget at the time. I went old-school with a Wadkin RS8 pattern makers lathe. You get a lot of cast iron for your money with these old machines. It was 75 years old this year (built in 1950) and I gave it a VFD for its birthday present. It does everything I ask of it and never lets me down.

Lathe tour here if interested (on my new YouTube channel)

Richard

View attachment 79361

Mark Hepburn

Artist & Chef

Got my dream lathe ten years ago. VB 36 just before Steinert took over. It’s beast I’ll never fully realize the potential of

Last edited: