I've done composite work on boats and RC gliders in the past. Mostly with West Systems epoxy. I know most turners use casting resins. Using epoxy resins was always fraught with hazards of skin sensitivity issues from the resin and dust exposure. I see a lot of turners on line demonstrating their work without any precaution from the dust or shavings. My question is casting resin less toxic than traditional epoxy like West Systems and does it stink!

-

January 2026 Turning Challenge: Turned and Bent! (click here for details) -

Congratulations to Phil Hamel, People's Choice in the December 2025 Turning Challenge (click here for details) -

Congratulations to Ric Taylor for "Black Ash Burl" being selected as Turning of the Week for January 26, 2026 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Epoxy Resin Woodturnings

- Thread starter Tom Kamila

- Start date

Tom my West Systems Epoxy use has been on smaller parts (nothing like boats) and I have and use lot of epoxy resins. I have never been offended by odor and I have had no adverse reactions to skin or anything.

Thanks Bill.Tom my West Systems Epoxy use has been on smaller parts (nothing like boats) and I have and use lot of epoxy resins. I have never been offended by odor and I have had no adverse reactions to skin or anything.

What I'm looking for are woodturners experienced with casting resins for turnings.

- Joined

- Feb 28, 2021

- Messages

- 1,790

- Likes

- 1,604

- Location

- Roulette, PA

- Website

- www.reallyruralwoodworks.com

My personal experience? Never again. I tried Resin, Epoxy and Acrylic blanks all three, besides smelling different (odors weren't a problem for me) resulted in an unholy at the mess at the lathe that took longer to clean it all up than it did to turn the project... Long, (VERY LONG) stringy shavings that tangled and wrapped around the spindle, live center, tools, project, and tool rest... had to stop and clean away the mess (more frequently the better) and then there were those static-clingy shavings that stuck to, well, everything, and just couldn't be simply brushed off. That decided me right then and there, never again will I turn epoxy, resin, plastic, acrylic, etc. So other than that, I couldn't tell ya.Thanks Bill.

What I'm looking for are woodturners experienced with casting resins for turnings.

I use Alumilite urethane resin for my lidded boxes and pens. No odor, fast setting, and nice to turn. But you do need a pressure pot. In regards to the strings that wrap around the spindle, I keep a small wire brush handy. Just a quick swipe with the brush while the lathe is spinning pulls the strings right off.

...casting resins...

My personal experience? Never again.... Long, (VERY LONG) stringy shavings that tangled and wrapped around the spindle, live center, tools, project, and tool rest...

I've had that problem with turning cast acrylic - at first I got a bird's nest of plastic strands balled up around everything, had to stop regularly to pull and/or cut the strands away - what a pain.

What solved it for me was moving the DC pickup nozzle closer, to just behind the work. (The DC is a powerful 5hp cyclone) Then the entire yards-long strand will be pulled into the pickup as it leaves the tool. It's a fascinating thing to watch. I should make a little video!

Examples of cast acrylic turnings (sorry, I've posted this a time or two before)

Turning aluminum can also make strands but they are not as pernicious as plastic strands and typically don't wrap around things since they are less flexible and tend to break. A pile does usually collect on the lathe bed. This is from the doc I posted here on turning metals, mostly aluminum and brass) on the wood lathe. (The doc includes a bit about turning plastics.)

JKJ

I'm not a big fan of microplastics in the environment. I would suggest segregating plastic swarf from wood and landfilling it.I've had that problem with turning cast acrylic - at first I got a bird's nest of plastic strands balled up around everything, had to stop regularly to pull and/or cut the strands away - what a pain.

What solved it for me was moving the DC pickup nozzle closer, to just behind the work. (The DC is a powerful 5hp cyclone) Then the entire yards-long strand will be pulled into the pickup as it leaves the tool. It's a fascinating thing to watch. I should make a little video!

Examples of cast acrylic turnings (sorry, I've posted this a time or two before)

View attachment 80808

Turning aluminum can also make strands but they are not as pernicious as plastic strands and typically don't wrap around things since they are less flexible and tend to break. A pile does usually collect on the lathe bed. This is from the doc I posted here on turning metals, mostly aluminum and brass) on the wood lathe. (The doc includes a bit about turning plastics.)

View attachment 80809

JKJ

i use designer epoxy based in quebec canada. they ship free to canada and the USA. their product is odorless.I've done composite work on boats and RC gliders in the past. Mostly with West Systems epoxy. I know most turners use casting resins. Using epoxy resins was always fraught with hazards of skin sensitivity issues from the resin and dust exposure. I see a lot of turners on line demonstrating their work without any precaution from the dust or shavings. My question is casting resin less toxic than traditional epoxy like West Systems and does it stink!

i use designer epoxy based in quebec canada. they ship free to canada and the USA

I'm not a big fan of microplastics in the environment. I would suggest segregating plastic swarf from wood and landfilling it.

When dumping the dust bin you can pull out much of the plastic from the pile with your fingers - most is still in long, thread-like strands. A forked tool with widely separated smooth "tines" such as we use with livestock can help. A better solution might be to use a screen somewhere in the DC collection stream when turning plastics and resins, perhaps at the or behind the pickup nozzle or stretched over the bin under the lid.

However, I suspect that burying plastics in landfills doesn't stop the environmental problem of microplastics since plastics are in almost everything today.

"Plastic never goes away — it just breaks down into finer and finer particles..."

Microplastics and our health: What the science says

Whether we know it, or like it, our bodies are polluted by tiny fragments of plastic that fail to break down in our earthly environment. What does that mean for our long-term health, and what can we do about it?

The solution may be to use a time machine and prevent the invention of plastic. Or require huge deposits on anything made of plastic. Things today would be different... On a wilderness trail in the Cumberland mountains yesterday I was amazed at the amount of plastic trash our fellow humans had thrown down the hill.

JKJ

Please take my thoughts / experiences with a grain of salt as I'm very new to this.

The desire to turn epoxy resin / wood projects is what got me started here.

I've used strictly epoxy resin.

Quick drying, regular and deep pour.

None of the different types / brands I've used have had much of a discernible smell when mixing and casting.

I do wear latex gloves when working with it.

When sanding I wear a mask with carbon filters made by 3M, it's good enough to spray automotive type paint, and a face shield.

A pressure pot is a must, a vacuum pot is nice as well.

A small air compressor is all you need for the pressure pot. like one for nail guns as they don't require a lot of volume.

I made a pressure pot from a cheap Amazon painters pot.

Total cost was under $80.00 with the extra fittings I used and better a gauge.

The vacuum chamber is a Chinese Vevor unit that was less than $180.00 including the pump.

It pulls a 29hg. vacuum in about 2 minutes and holds it overnight.

I started with a set of cheap Chinese carbide turning tools that worked just ok.

The handles were short and they chattered badly at times, scattering chips all over my reloading bench and Harley.

I gave them away to the same guy I gave my old Craftsman lathe to.

The Sorby HSS tools that came with my new to me lathe worked better but dull quickly.

All the better to hone my sharpening skills, pun intended.

I bought a three tool set designed for turning epoxy resin from Simple Woodturning tools.

They arrived Friday and I used them for the first time yesterday.

The difference was dramatic.

I guess it's like comparing Snap-on sockets and wrenches to Harbor freight units.

As others have said, the shavings do get tangled up in everything.

I looked like I was covered in spiderwebs when I was done yesterday.

I hope this helps, like I said, I'm just getting started down this rabbit hole.

Here's a couple of photos for things I've made and my lathe after I was done yesterday.

Craig.

The desire to turn epoxy resin / wood projects is what got me started here.

I've used strictly epoxy resin.

Quick drying, regular and deep pour.

None of the different types / brands I've used have had much of a discernible smell when mixing and casting.

I do wear latex gloves when working with it.

When sanding I wear a mask with carbon filters made by 3M, it's good enough to spray automotive type paint, and a face shield.

A pressure pot is a must, a vacuum pot is nice as well.

A small air compressor is all you need for the pressure pot. like one for nail guns as they don't require a lot of volume.

I made a pressure pot from a cheap Amazon painters pot.

Total cost was under $80.00 with the extra fittings I used and better a gauge.

The vacuum chamber is a Chinese Vevor unit that was less than $180.00 including the pump.

It pulls a 29hg. vacuum in about 2 minutes and holds it overnight.

I started with a set of cheap Chinese carbide turning tools that worked just ok.

The handles were short and they chattered badly at times, scattering chips all over my reloading bench and Harley.

I gave them away to the same guy I gave my old Craftsman lathe to.

The Sorby HSS tools that came with my new to me lathe worked better but dull quickly.

All the better to hone my sharpening skills, pun intended.

I bought a three tool set designed for turning epoxy resin from Simple Woodturning tools.

They arrived Friday and I used them for the first time yesterday.

The difference was dramatic.

I guess it's like comparing Snap-on sockets and wrenches to Harbor freight units.

As others have said, the shavings do get tangled up in everything.

I looked like I was covered in spiderwebs when I was done yesterday.

I hope this helps, like I said, I'm just getting started down this rabbit hole.

Here's a couple of photos for things I've made and my lathe after I was done yesterday.

Craig.

Have used Alumilute up until now with no noticeable odor. Going to switch though ...

Next resin project will be with using - Liquid Glass SuperClear Deep Pour Epoxy Casting Resin 2:1

Going to try switching since Alumilite has only a 12 min work time and that can get a bit hectic.

Starting out, I wasn't happy using any of my existing gouges and/or scrapers until I the found these two tools (total game changers ... at least for me ) -

1 - Keith Lackner's Signature series "The Axe" from Carter Products (only thing I've ever bought there) ... pretty pricey but made a huge difference ... cuts resin like butter ... never had a catch.

2 - Simple Woodturning Acrylic Resin scrapers -Simple Scraper II and their AR Simple Scraper I ... amazing for smoothing out previous cut lines in the resin.

I use a California Air 5 gal pressure pot and their vacuum conversion kit for it as well (with a cheese-oh 4.5 CFM vacuum pump).

Next resin project will be with using - Liquid Glass SuperClear Deep Pour Epoxy Casting Resin 2:1

Going to try switching since Alumilite has only a 12 min work time and that can get a bit hectic.

Starting out, I wasn't happy using any of my existing gouges and/or scrapers until I the found these two tools (total game changers ... at least for me ) -

1 - Keith Lackner's Signature series "The Axe" from Carter Products (only thing I've ever bought there) ... pretty pricey but made a huge difference ... cuts resin like butter ... never had a catch.

2 - Simple Woodturning Acrylic Resin scrapers -Simple Scraper II and their AR Simple Scraper I ... amazing for smoothing out previous cut lines in the resin.

I use a California Air 5 gal pressure pot and their vacuum conversion kit for it as well (with a cheese-oh 4.5 CFM vacuum pump).

It's good to hear none of you have experienced any sensitivity to the epoxy. With west Systems it is also possible to become sensitized from sanding dust . I'll probably go with Liquid Glass that some of you have recommended. I think I purchase from Fiberglass Coatings in the past as the name is familiar.

Thanks guys!

Thanks guys!

Epoxy sensitivity is a real thing, especially amongst heavy users like boat builders. It's good practice to keep the air as free of catalyzation off-gassing and sanding dust as possible.

In regard to the dangers of resin dust ... one important thing I discovered with the sanding phase on hybrid projects is to always wet sand before the finish and buffing stages.

It works great to remove fine resin lines, keeps the sandpaper clean throughout the process, produces a great surface for finishing and virtually eliminates any airborne dust.

Found this to be a good deal for fine grit wet sandpaper - 90 Pcs 400 to 3000 Grit Wet Dry Sandpaper Assortment 9x3.6 Inch for Automotive Sanding - Furniture Finishing - Wood Turing Finishing

Lots of youtube vids on the virtues of wet sanding ... here's one from Sam Angelo (wyomingwoodturner)

I've always used water as the lubricant.

Hope this helps

It works great to remove fine resin lines, keeps the sandpaper clean throughout the process, produces a great surface for finishing and virtually eliminates any airborne dust.

Found this to be a good deal for fine grit wet sandpaper - 90 Pcs 400 to 3000 Grit Wet Dry Sandpaper Assortment 9x3.6 Inch for Automotive Sanding - Furniture Finishing - Wood Turing Finishing

Lots of youtube vids on the virtues of wet sanding ... here's one from Sam Angelo (wyomingwoodturner)

I've always used water as the lubricant.

Hope this helps

Last edited:

Found this to be a good deal for fine grit wet sandpaper - 90 Pcs 400 to 3000 Grit Wet Dry Sandpaper Assortment 9x3.6 Inch for Automotive Sanding - Furniture Finishing - Wood Turing Finishing

Is this paper flexible, such that you can fold it tightly will not crack at the fold? (Some inexpensive wet-sanding paper is not.)

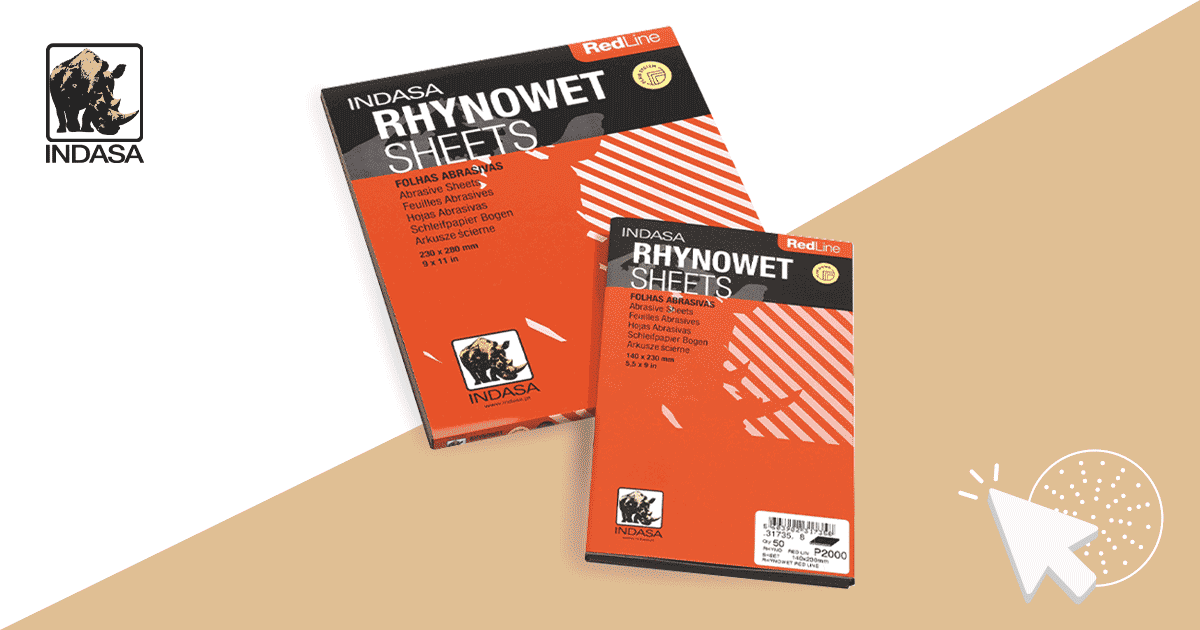

The flexibility is one of several things I love about Indasia Rhynowet Red Line sandpaper. I use it from 400 to high grits - mostly use 600-1200 grit. Comes in 9x12 sheets, I think, which I cut into 3"long narrow strips to use. I buy boxes of 50 sheets and have a lifetime supply on the shelf.

RHYNOWET RED LINE

Lightweight and easy to sand abrasive sheet. Looking for waterproof sandpaper for stock removal? Click to find out more about our Rhynowet Red Line

www.indasa-abrasives.com

I mostly dry sand (by hand) but do a but of wet sanding with fine paper, both with water for acrylics and with oil or another finish on hard woods. I use different brand of paper for coarser grits.

Is this paper flexible, such that you can fold it tightly will not crack at the fold? (Some inexpensive wet-sanding paper is not.)

Yes, paper folds without cracking or abrasive coating flaking off ... seems to work fine ... will check out Rhynowet Red Line as well ... thx.

Shoot, I drove by Camp Verde just a few weeks ago. I could have brought some samples!

DangShoot, I drove by Camp Verde just a few weeks ago. I could have brought some samples!