An article on CBN from a foreign abrasives manufacturer.

reliableabrasives.com

reliableabrasives.com

Another article-

www.cdtusa.net

www.cdtusa.net

Yet another-

info.eaglesuperabrasives.com

info.eaglesuperabrasives.com

What's the application of CBN Wheels? - Reliable Abrasives - Precision in Every Particle

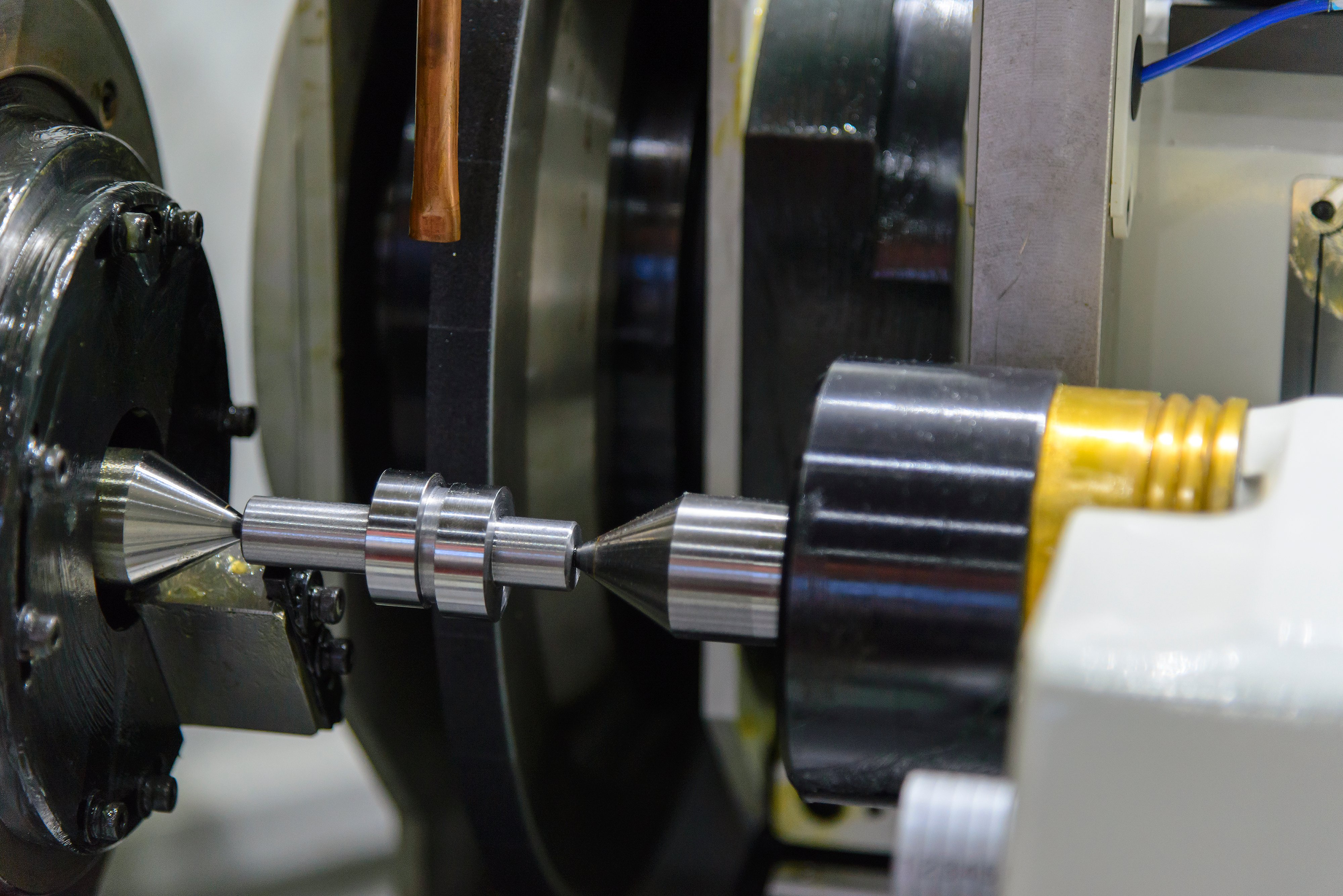

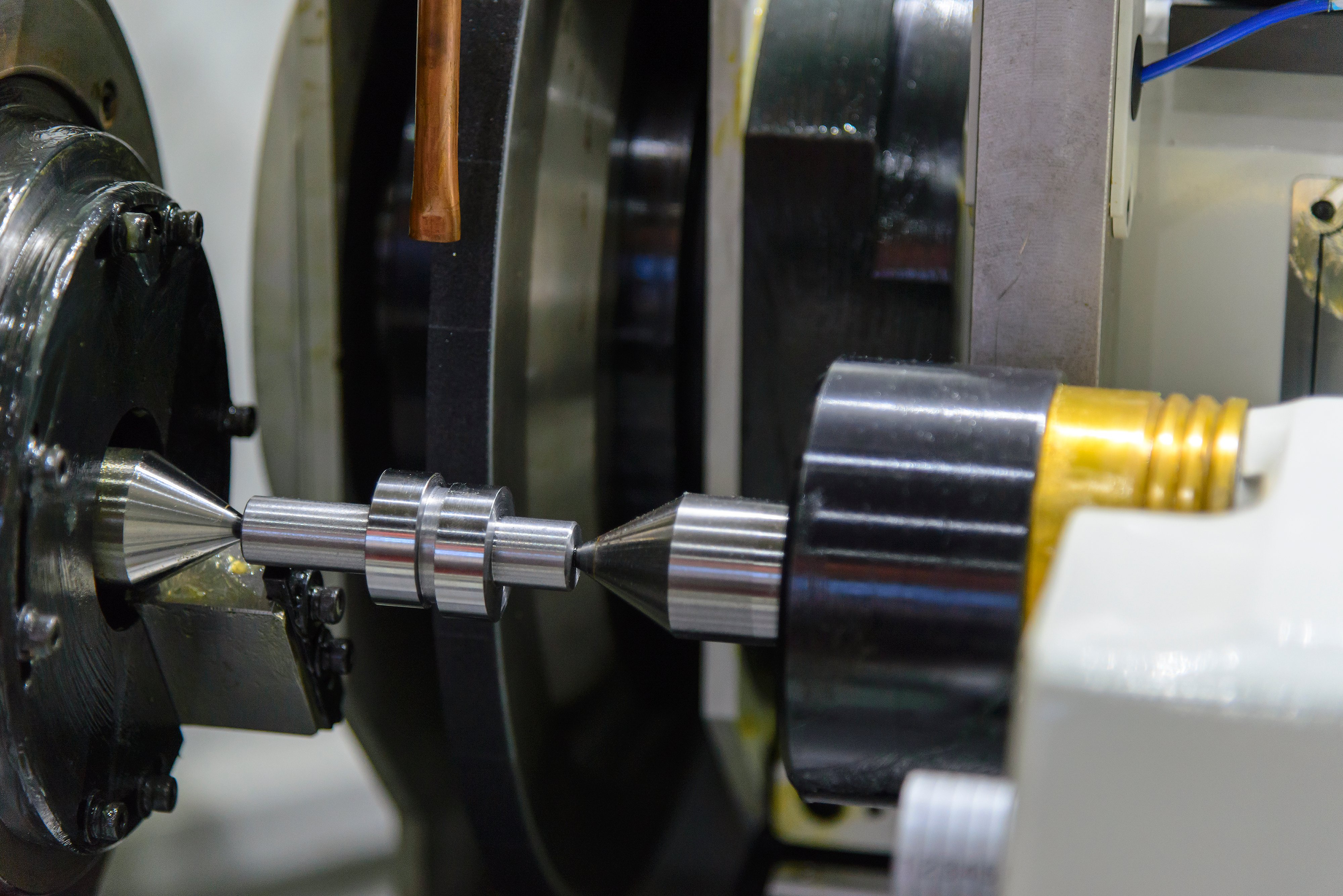

Struggling with grinding hard steels? Frequent wheel changes and poor finishes can hurt your bottom line. We have found that CBN wheels provide the durability and precision you need. CBN (Cubic Boron Nitride) wheels are used for precision grinding of hard ferrous materials. Common applications...

reliableabrasives.com

reliableabrasives.com

Another article-

Why Different Materials Need Different Grinding Wheels

With all of the grinding wheel options available, figuring out which one is going to be the most efficient and cost effective for your working material can feel overwhelming, but CDT is here to help.

Yet another-

Ultimate Guide to CBN Grinding Wheels

Discover the ultimate guide to CBN grinding wheels: explore their benefits, applications, and how they outperform conventional wheels for precision and efficiency.

info.eaglesuperabrasives.com

info.eaglesuperabrasives.com

Last edited: