I built a Rose Engine lathe for ornamental turning, and it uses a fly cutter. These cutters are made from 3/16" diameter rod, and are short. Two of my cutters are shown below :

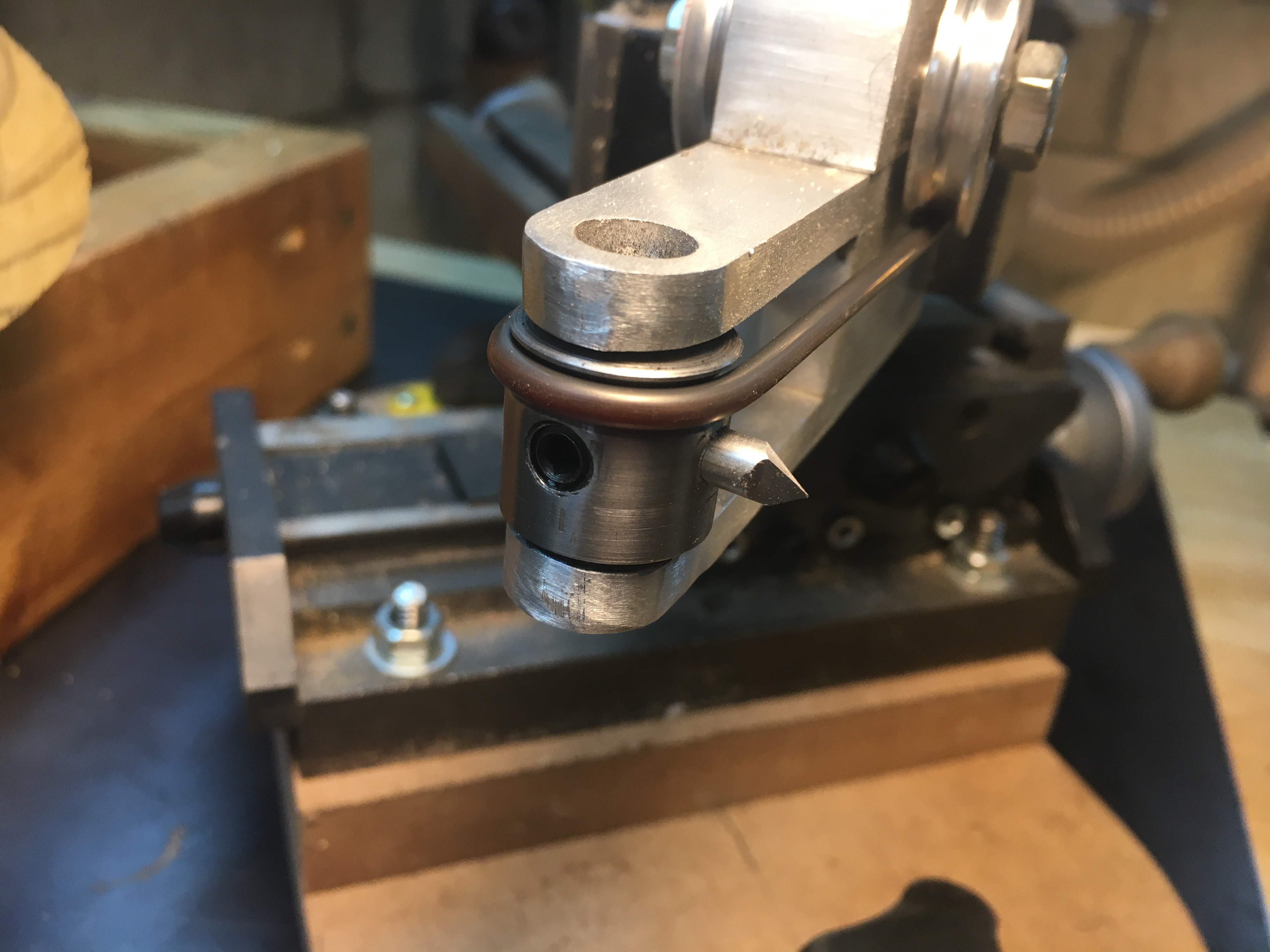

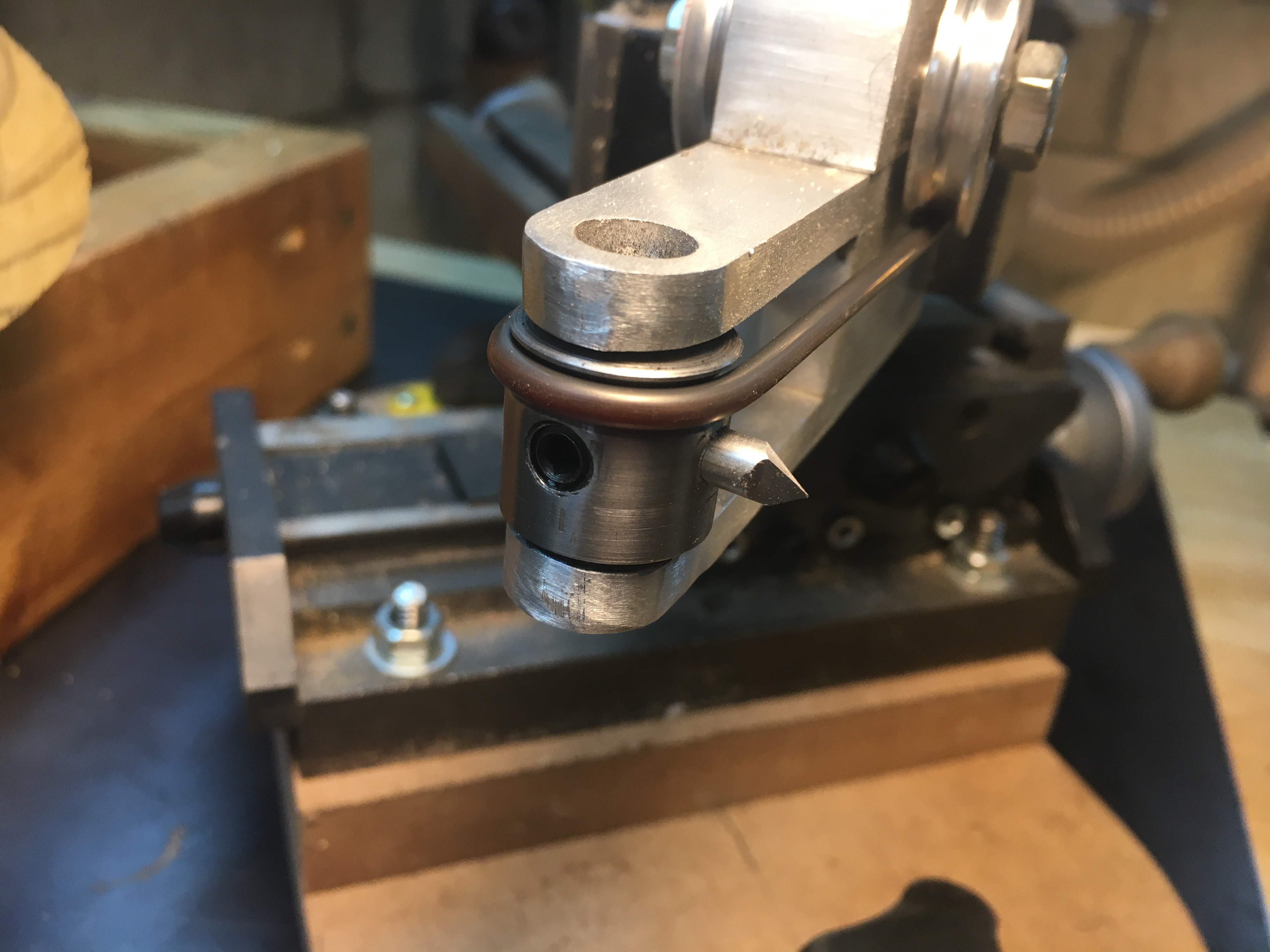

The fly cutter is mounted in a cutting frame (yes, I had to make that too, but Bill Ooms' site was super helpful). The cutting frame and fly cutter are shown below :

I've been trying to think of a way to sharpen these cutters. To date, I've held them in a hand-held drill, and sharpened them by using the drill to rotate the cutter whilst running along the grindstone. This leaves a lot to be desired in the way of accuracy and cleanliness of the cut.

I was going to build a variation on a goniostat, but this is a bit complicated, and is meant to sharpen the tool on a flat surface. Adapting it to the Tormek would be difficult.

Today, I came upon this idea. It is a two-piece jig that I made today on my metal lathe. The pieces are shown below separated, and together :

The rod is ¾" diameter, hot-rolled steel, and the collar is aluminum.

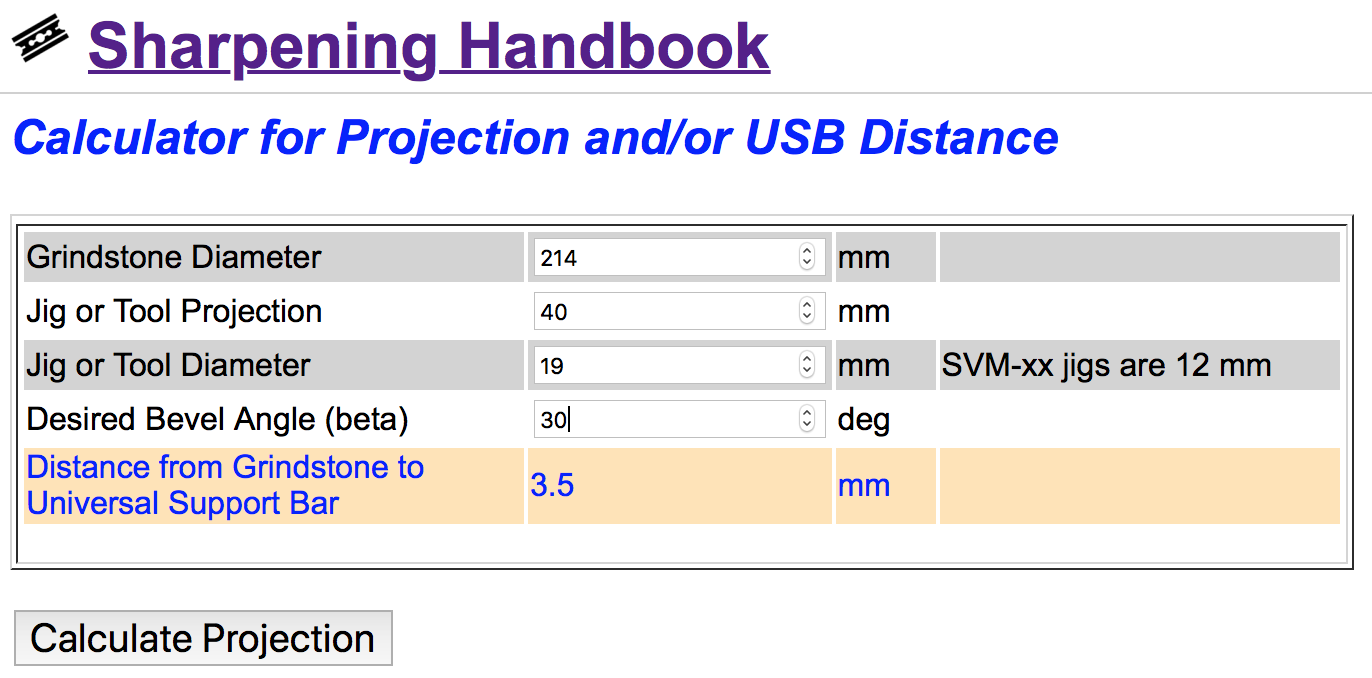

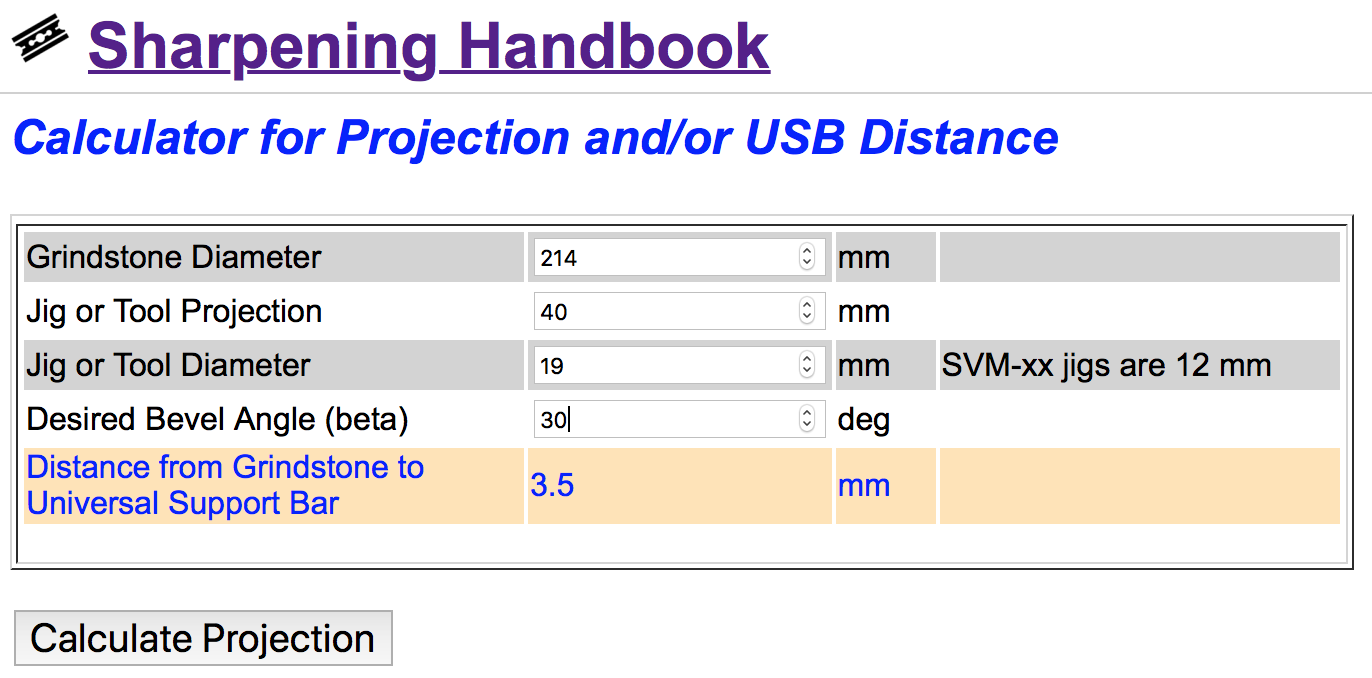

The calculations used for sharpening the cutter are :

When the cutter is mounted in the jig and held against the wheel, this is how it looks :

The measured angle is exactly as needed, and this works wonderfully.

if you want more details, please contact me.

Rich

The fly cutter is mounted in a cutting frame (yes, I had to make that too, but Bill Ooms' site was super helpful). The cutting frame and fly cutter are shown below :

I've been trying to think of a way to sharpen these cutters. To date, I've held them in a hand-held drill, and sharpened them by using the drill to rotate the cutter whilst running along the grindstone. This leaves a lot to be desired in the way of accuracy and cleanliness of the cut.

I was going to build a variation on a goniostat, but this is a bit complicated, and is meant to sharpen the tool on a flat surface. Adapting it to the Tormek would be difficult.

Today, I came upon this idea. It is a two-piece jig that I made today on my metal lathe. The pieces are shown below separated, and together :

The rod is ¾" diameter, hot-rolled steel, and the collar is aluminum.

The calculations used for sharpening the cutter are :

When the cutter is mounted in the jig and held against the wheel, this is how it looks :

The measured angle is exactly as needed, and this works wonderfully.

if you want more details, please contact me.

Rich