I purchased a steel blank 10mm x 20 mm x 200 mm.

I plan to grind a scraper on one end to be a square and on the other end to have a profile for the left side bowl.

I was just thinking about making a wooden handle with two pins that register and could be removed and the scraper turned around.

Then I ran across this:

www.ashleyharwood.com

www.ashleyharwood.com

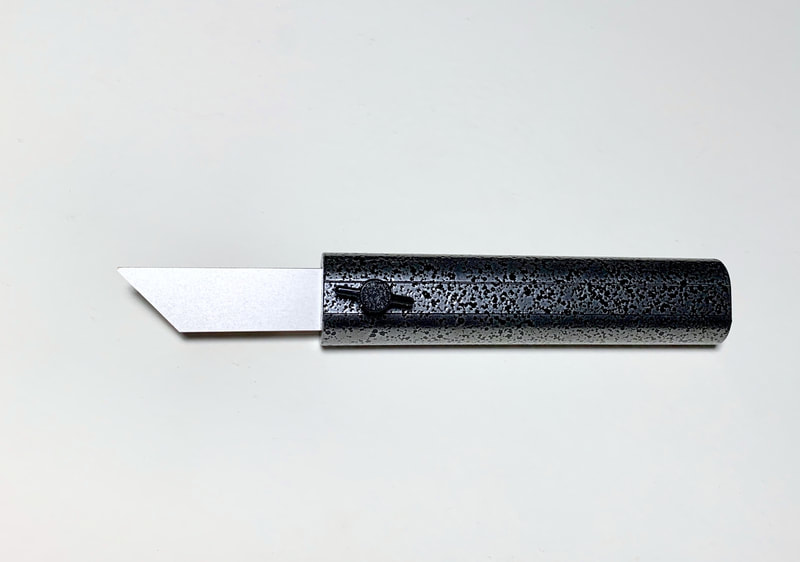

A magnetic catch for a scraper handle.

Does anyone have experience or tips for making a handle for a reversible scraper?

I plan to grind a scraper on one end to be a square and on the other end to have a profile for the left side bowl.

I was just thinking about making a wooden handle with two pins that register and could be removed and the scraper turned around.

Then I ran across this:

Double Ended Negative Rake Scraper and Handle Package — Ashley Harwood Woodturning - Turning Native LLC

Available now! This is my new, patent pending negative rake scraper system. The double ended scraper provides two different profiles, and the magnetic handle makes it easy to switch between blades with no set screws or allen keys required. And don’t worry, the magnets don’t touch the blade, so the

A magnetic catch for a scraper handle.

Does anyone have experience or tips for making a handle for a reversible scraper?