Curious, what woods would you recommend for practicing texturing? I have watched numerous videos on it, and I have a general idea of how the various tips can be used, but its the actual getting a good texture/not shredding fibers that needs work

I've never watched a video on texturing. I just make up ideas and try them.

Best woods for the type of texture on that Bubinga tool handle are hard and fine-grained - cut cleaner. Best woods for a texturing tool are nearly any.

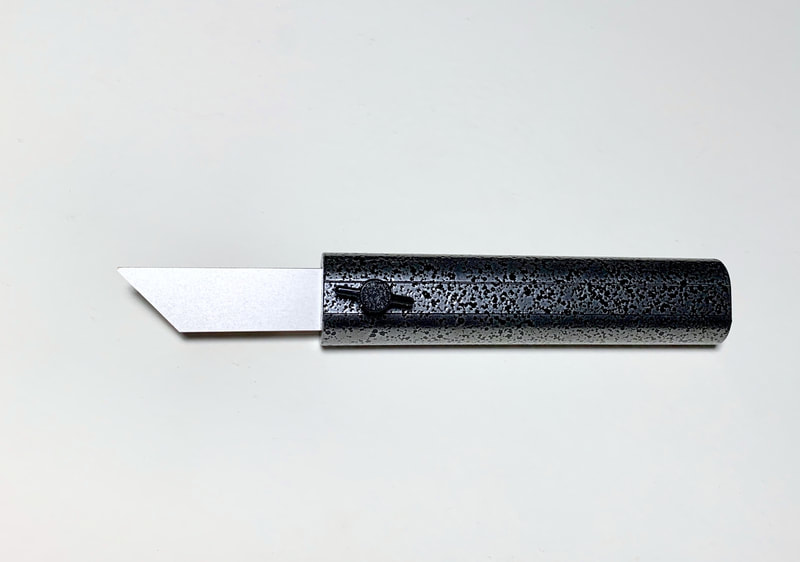

Note that the texture on that handle is not from a texturing tool but stippling with a dremel with a small, oval-shaped carbide burr. The stippling is simply a few hundred little craters carved into the wood, one at a time. Takes a while. I draw two lines, texture between the lines, then use a skew to make a v-groove to clean up the borders since nobody is perfect.

Some good woods for stippling are ebony, blackwood, purpleheart, dogwood, rosewoods, lignum vitae, bradford pear, etc - the harder the better. Lots of exotics are great. Some good woods for practicing textures are anything cheap.

I'll use a spiral or pointed star wheel texture tool on almost any wood - turn, smooth, texture, then apply finish. The star wheels are very quick and easy. Spiral texturing wheels are a pain and can be difficult to predict.

I described this in detail in the document I uploaded on texturing.

I also use other texturing methods I didn't put in the document.

These horse rider's crop handles have a variety of textures.

I define a texture on a handle as anything that gives a better grip.

JKJ