I just watched the Ray Key box videos posted by CSUSA. He had an interesting finishing schedule that consisted (as near as I can tell from the videos) of sanding to 400 with some kind of wax as a sanding lubricant (he said it reduced heat and scratch marks), polishing with 0000 steel wool with the same wax as a lubricant, then applying (what I think was) lacquer based sanding sealer on the lathe, using heat to dry it quickly, then cutting back the sheen with 0000 steel wool, then finishing wax over that. Seems like an interesting protocol that I'd like to try. Timestamp link to one instance of the protocol:

View: https://youtu.be/PTZemwWM2mE?si=OfwKZRV1pzYhkTuQ&t=531

Questions:

Does anyone know more about the wax used for sanding lubricant? (He refers to it simply as "paste wax" and the labels of everything are strategically facing away from the camera in the videos).

Is the lacquer product used a sanding sealer?

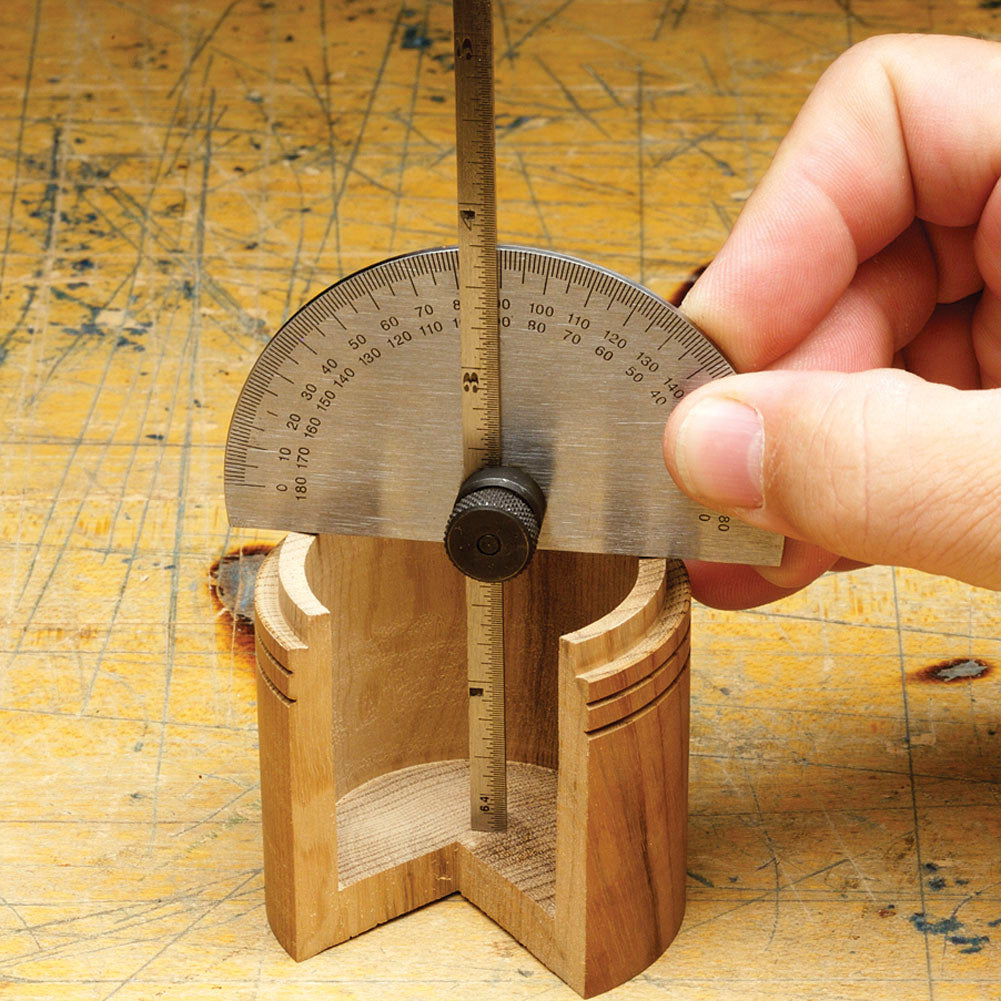

Anyone have a bead on where to get a depth gauge with a nice wide base like the one shown here?:

View: https://youtu.be/PTZemwWM2mE?si=gDUvnF0h_51cQbS7&t=501

As an interesting aside, I have one of Ray's tools. He taught at Arrowmont so much that he just left a set there, and in 2016 when it became apparent he wouldn't be able to make it back out, he asked Nick Agar to sell them off to the class that was there at the time. I was in that class and picked up a very well worn scraper- a wonderful piece of history and inspiration for me to carry the craft of box-making forward!

Questions:

Does anyone know more about the wax used for sanding lubricant? (He refers to it simply as "paste wax" and the labels of everything are strategically facing away from the camera in the videos).

Is the lacquer product used a sanding sealer?

Anyone have a bead on where to get a depth gauge with a nice wide base like the one shown here?:

As an interesting aside, I have one of Ray's tools. He taught at Arrowmont so much that he just left a set there, and in 2016 when it became apparent he wouldn't be able to make it back out, he asked Nick Agar to sell them off to the class that was there at the time. I was in that class and picked up a very well worn scraper- a wonderful piece of history and inspiration for me to carry the craft of box-making forward!