I just watched the last video of the 4-part series by

@Richard Findley,

Turn Better Bowl - Episode 4. Excellent!

View: https://www.youtube.com/watch?v=fyoJRvolrF8

Richard is a joy to watch - tool control is incredible. And he makes some excellent points - one many people skip and pay for it later is to feel the surfaces carefully with the fingers to reveal even small irregularities that may be invisible - until the finish is applied and cured!! So true - I've seen so many otherwise beautiful pieces avoidably degraded. Some of most most noticable and avoidable embarassments are humps or depressions inthe left in center and inside curves of bowls or platters. (I feel the surfaces often while turning..But the finer can feel wat the eye might not see.

When I find these while turning I mark them carefully with a pencil then turn away the pencil marks.) When off the lathe I use a different method hand scrapers to fix but the effect is the same - a perfect surface.

For those who may have missed these, start with Episode 1. Well worth watching the series even for those who may not turn a lot of bowls. Richard shows and explains

everything clearly!

.

I've never used the Hard Wax Oil but now I want to try it! Especially that with the whte pigment. I prefer a satin finisn on most things.

-----------------------------------------------------------------------------------------------------------

Related to Richard's comment about buying small cans of the finish since what's unused can set up and be ruined,

I have something to consider. I've written about this several times before but for those not familiar: I've solved this problem in my shop years ago: Before resealing the lid on a can or bottle I displace the air inside with inert gas. (I do this for large bottles of CA glue too.)

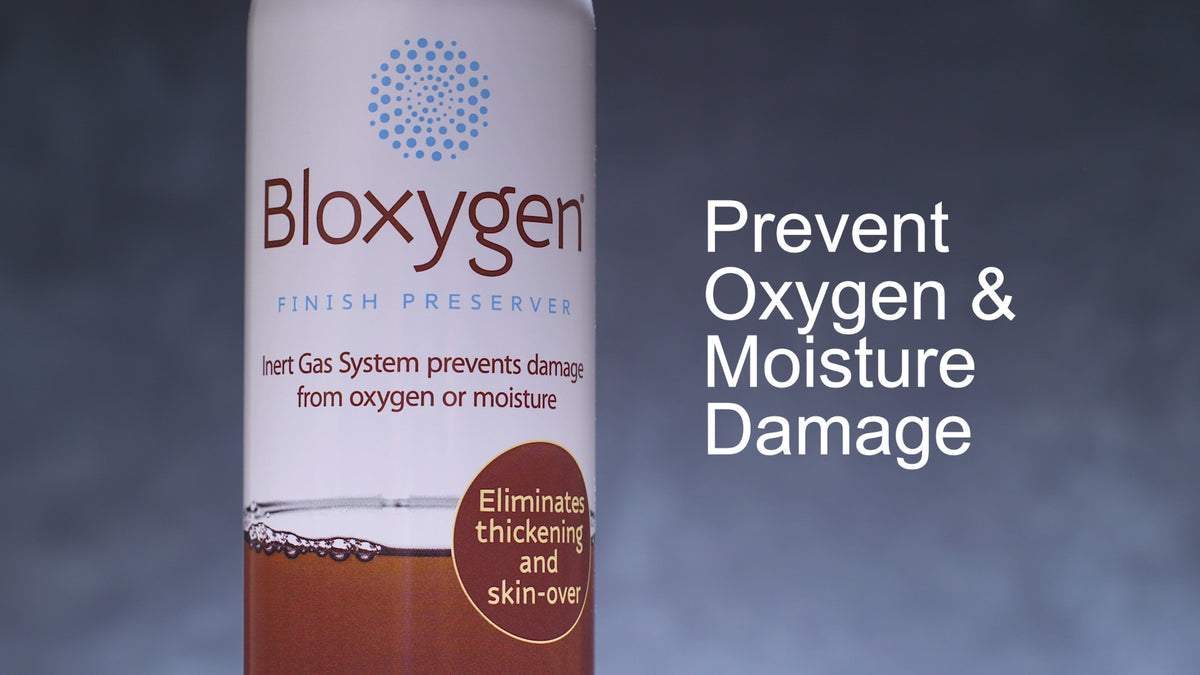

I've used several types of gas over the years but now stick with straight Argon. This is also the exact method used by the Bloxygen people - with no air touching the liquid surface most finish won't set up or even skim over. Seems better to prevent instead of trying to rescue, the topic of this thread:

my more recent approach is stop loss bags, or bloxygen...and you have shared about using a neutral gas before

I've written about this too: at one time the gas in a Bloxygen can was a mixture of Nitrogen, Argon, and CO2.

At some point they switched to pure Argon. At the time they said they discovered that the CO2 could react with chemicals in certain finishes. I think they went to Argon since it's heavier that Nitrogen and even if the air in the can wasn't completely displaced, a layer of Argon could settle inside the can and still protect the finish. Years ago...

I no longer have partially filled cans Watco danish oil or other finishes go bad on the shelf. A good test is with Birchwood Casey's TruOil gunstock finish, notoriously quick to set up once opened. (I wonder if that's one reason they offer TruOil in tiny bottles!) I've not once had TruOil set up since I started using the inert gas. One larger bottle in my shop, 1/2 used, is still like new after a bunch of years.

Hardware I use. Near my lathe I keep a compressed gas cylinder stolen from my little welding shop. Since most turners may not have a cylinder` there would a cost to buy a tank and a regulator. (It could be a small tank is cheaper than what I use.) But you only buy it once and you can use it from then on. The cylinder I use (size Q) will probably still be mostly unused when I'm gone! The gas itself is cheap.

To supply the Argon to the finish contanerss I put a hose fitting such as shown below on the regulator and push on a length of plastic tubing.

Method of use

Method of use Turn on the gas keeping the pressure very low and let gas flow through the tube gently into the container so it doesn't splash the liquid much! I usually add enough argon to displace all the air but all that's really needed is enough for a layer on top the finish. (Argon is heavier than air.) Then pull out the hose and quickly cap the container.

This method is probably not for everyone but works well for me. I like this far better than dealing with stop-loss bags, the marble method, etc. I can keep lots of different finishes in their original containers and even those I've opened but rarely use never go bad.

Possible options to lower the cost would be buy a smaller tank and use an inexpensive helium balloon filler instead of an industrial regulator. Bending the flexible filler nozzle controls the gas flow. (If anyone is interested I could try attaching tubing to one of my helium balloon tanks.)

Or simply buy a can of Bloxygen. Based on their website, one can should last a

long time with small containers - they claim one can of Bloxygen can preserve quart size cans of finish 75 times..

Frequently Asked Questions

www.bloxygen.com

JKJ