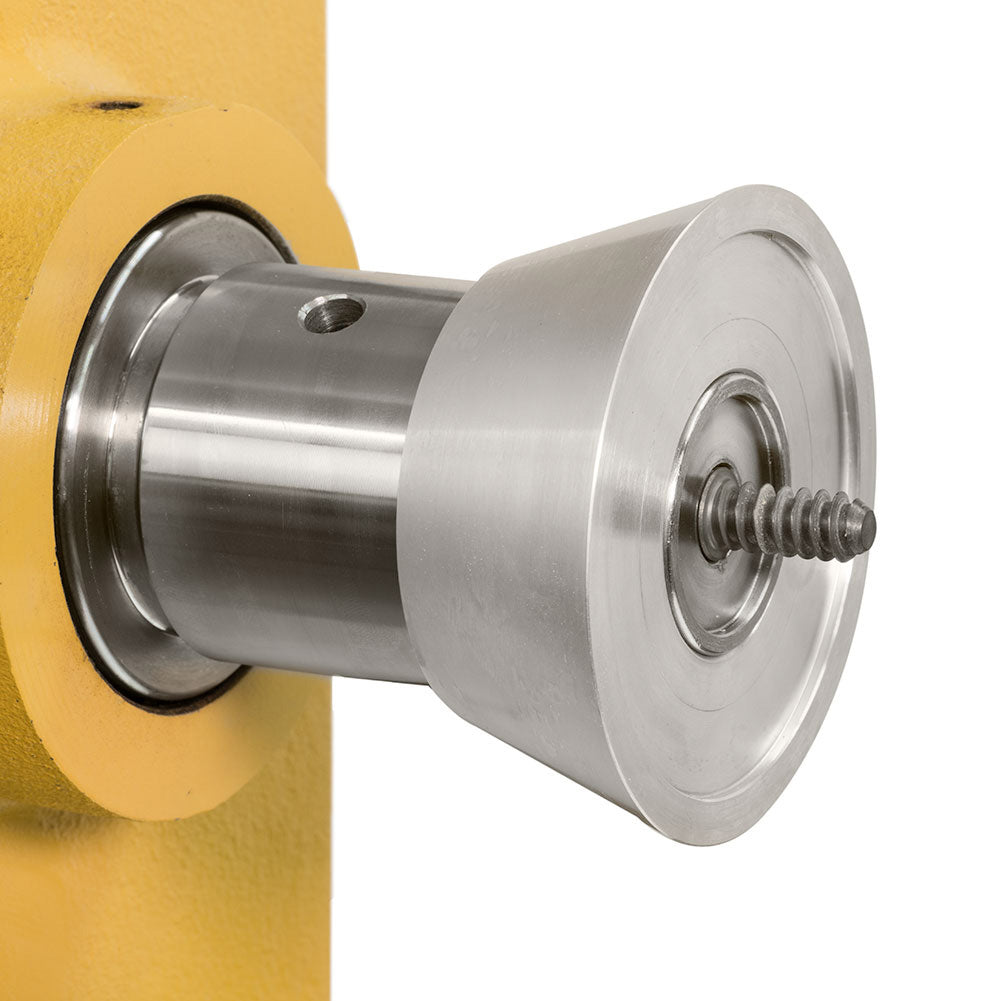

I generally use a screw chuck when I am rough turning my bowls. I have been using the screw supplied with my Nova chucks, but just recently got the Craft Supply 3 in 1. It arrived well boxed and protected in its own form fitting foam insert. The machining on this piece is just flat pretty. Everything fits beautifully together and functions just like it should; a nice piece of craftsmanship on the manufacturer's part. I offers a lot of flexibility in its design and I think that it will provide enough options to turn just about any size bowl I want to make.

Wally

Wally