- Joined

- Jan 7, 2010

- Messages

- 2

- Likes

- 0

Hi Guys

New to the forum, thanks for your hospitality.

I started woodturning to make hickory handles for my Tomahawks.

Heres the question: How do you turn a handle that isnt quite a round shape ?

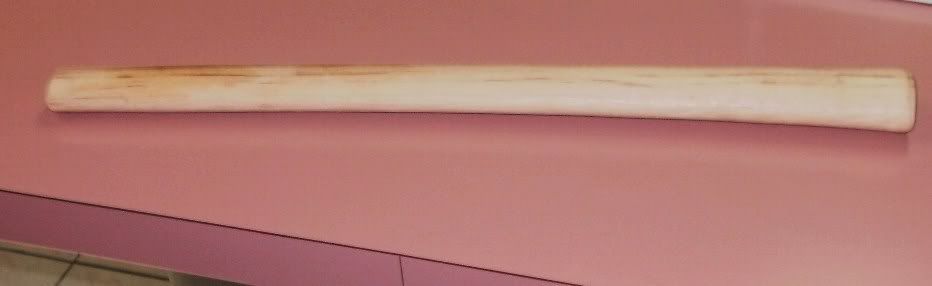

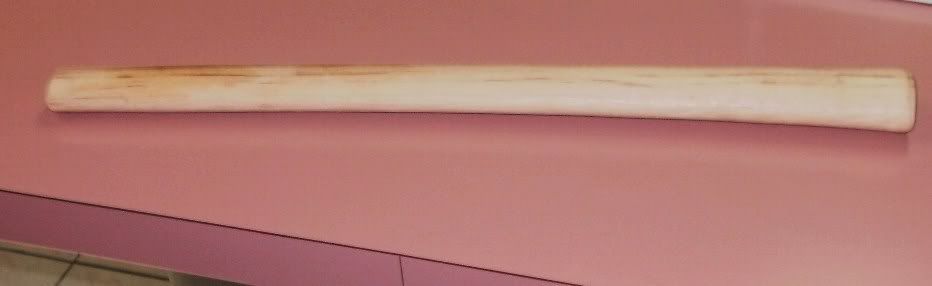

Heres images of what I'm trying to do ( these are pro made handles ).

Any help ?

New to the forum, thanks for your hospitality.

I started woodturning to make hickory handles for my Tomahawks.

Heres the question: How do you turn a handle that isnt quite a round shape ?

Heres images of what I'm trying to do ( these are pro made handles ).

Any help ?