Hi Bud,

I have used more systems than I care to admit. One of my big complaints, including with the Tormek systsem, was that I often regrind several times within minutes of each other. Right now I am working on initial shaping of a beautiful burl and that baby takes the edge off a gouge in a big hurry! I find it particularly difficult (dangerous, catch likely) to use anything but a razor sharp gouge for interrupted cutting. My latest setup was 2 Stuart Batty Large grinding platforms (no longer available) and 2 Robo Hippys. I really wanted the RoboHippy platform to be a bit larger (to resist operator error of slightly lifting the handle of the gouge while grinding and thereby messing up the grinding angle). Because I have 2 grinders and 4 angles set I rarely used the ability of the RoboHippy system to quickly change the grinding angle. I recently attended a turning workshop and had a chance to use the OneWay system including the optional Vari-Grind jig. I was really pleased with the results and it is FAST to use. Setup is no more than 60 seconds. The one I used at the workshop had a pair of custom locking rings on the slide. They were set for for 60 and 40 degrees. Slide it out until the 60 ring hits the stop and go. Slide it in until the 40 stop hits the stop and go. Didn't know about the trick of slightly bending the adjustment pin to tighten the platform. But it was really still an issue of wanting a larger platform.

More than anything this is about me and my own peculiarities. I might have to step up and admit to being lazy but I'd prefer to think I am reluctant to take a 5 minute break from turning every time I know the gouge isn't quite sharp enough. Anything I can do to make my shop work better for me, I'm likely to do it.

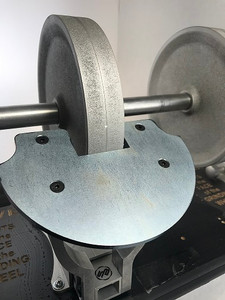

Incidentally, I found an old reference to the price of the RoboHippy grinding rest - $80. The grinding rests I bought were for the Wolverine system (integrated square tube base mounted at 45 degree angle). Not sure what value my bases add - maybe something, maybe nothing. I'll take some pics and add shortly.

Regards,

Tom